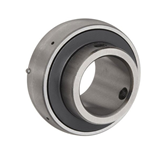

They therefore offer better running characteristics than other wheel bearings such as roller bearings or plain bearings. In the case of ball bearings, a further distinction is made between cone and precision ball bearings.

The major difference between these two versions is that precision ball bearings mainly absorb radial forces, while the cone version can absorb both radial and axial forces in one direction. In addition, the cone ball bearing can be disassembled and reassembled. The precision ball bearing is extremely low-maintenance and low-wearing which makes it particularly suitable for areas with strict hygiene regulations.

Similarly, the precision ball bearing - the highest quality bearing according to DIN - convinces with its excellent running properties, high load-bearing capacity and resistance. There are also special heat-resistant precision ball bearings which can be used at extremely high and low temperatures.

Choice of a suitable ball bearing

Together with other important factors, such as the tread, swivel bearing and wheel diameter, the bearing affects the quality of the entire castor. For this reason, it is always important to select the type of bearing best suited to individual requirements. Important factors here are the environment in which the castors are used, the load, and the duration and speed of use, for example. For particularly high demands, the precision ball bearing is best suited due to its excellent properties.

If you need help choosing the ideal ball bearing, contact us at Tente Castors & Wheels- we'll be pleased to help you get your project up and running!