Challenging Environment.

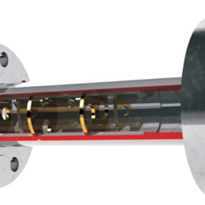

The bearings at the brewery, which are located on the rotating the filler heads of the capping machine, run under the most difficult of environments. They are submitted to continuous accelerations as part of the normal function of the machine. Furthermore, they are constantly exposed and drenched in the sugary media and washed down with aggressive cleaning agents daily.

FDA Approved bearings for the food industry

The CeramicSpeed range of Corrotec bearings are made from stainless steel rings, premium-quality ceramic balls, sealed and lubricated for life with a dedicated food-grade lubricant. In other words, the CeramicSpeed bearings are customized exactly for this machine and this customer. The physical properties of the ceramic balls make them interact with the bearing rings in an optimum way. They are 2.3 times harder than steel balls and extremely resistant to any otherwise corrosive media.

Still Running

After changing to CeramicSpeed Bearings, the bearings lifes has been increased more than 4 times - and they are still running without any problems. The brewery has reduced their downtime as well as their maintenance costs.

More Information

Contact CGB for more information and assistance.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)