Today, WOMA (Australia) Pty Ltd is a specialist business focussed on the B 2 B provision of quality and dependable Pressure & Vacuum Pumping and Explosion Protection solutions across key industrial sectors; Oil, Gas & Petro-chemical, Mining, Municipal, Infrastructure & Utilities, Defence, Manufacturing, Civils & Construction, Transportation including Material Handling, Shipping and Marine. Their talented team of experts offer Engineering, Service & Support, Spares, Accessories, Rental, Training and Consultative Services.

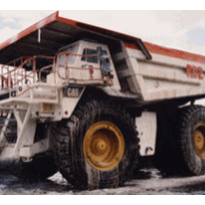

Established in 1982 by the entrepreneur Guy Jellicoe (recently recognised for his contribution to industry), it began with WOMA High Pressure Positive Displacement pump Sales and by necessity morphed in to the provision of contracting services. Over the subsequent two decades WOMA grew to become the southern hemispheres’ pre-eminent Industrial Services Contractor proudly supporting the largest fleet of high pressure pumps and servicing a range of ‘Blue-Chip’ clients including ALCOA, BHP, Rio Tinto, Woodside Energy, BP and Chevron to name a few. With operations in Australia, New Zealand and even Ireland and Jamaica it provided leading-edge industrial cleaning and maintenance activities and was the eminent industry fore-runner in the development of manipulator and semi-robotic tooling to remove the worker from the workface.

WOMA supplies high pressure and vacuum pump technologies and explosion protection solutions. They provide quality and dependability to clients from a range of sectors, including defence; infrastructure; construction; energy; and resources including shipping and marine, oil, gas, petrochemical and mining. They offer engineering, service and support, and also provide spares, accessories, rental, training and consultative services.

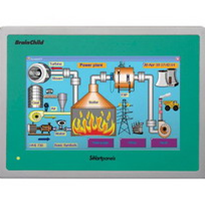

WOMA’s innovative industrial solutions include the ability to design using 3D Solid Edge software with additional proficiency in the application of Finite Elemental and Computational Fluid Dynamics analysis. In addition to their hazardous environment (ATEX and IECex) solutions, the experienced team offers bespoke and off-the-shelf engineered solutions with remote manipulation and robotic tooling to ensure worker and operational safety and productivity improvements. Turnkey dependability in hazardous environment solutions are available with applications from fork trucks and hydraulic power packs to air compressors, vacuum systems, high pressure pump systems and engine protection systems and conversions.

WOMA’s success in introducing leading edge technology to the Australian market is internationally recognised, and in keeping with that track record, they have again met a new benchmark with the successful introduction and integration of WOMA Miretti ATEX and IECex explosion protection OEM capacity to their operations. This single accomplishment facilitates a host of potential explosion protection solutions for the local Australian defence, marine and shipping sectors, as well as the mining, petrochemical, and the oil and gas sectors. WOMA Miretti are approved and certified to manufacture and supply products that comply with world-wide accepted standards in defence (land, air and sea) for equipment operating in hazardous areas, including, but not limited to, material handling assets (forklifts and loaders, etc) to mobility assets (such as troop carriers, refuel and transporter vehicles), through to static combustion engine protection systems powering sea-going support craft and main vessels.

WOMA Smart Solutions 2020: As a B 2 B supplier company, WOMA understand that aside of engineering, manufacture and sale of product or service, there must be an acknowledgement for the implementation of diversified peripheral services that make the difference; the ‘Smart Solutions 2020’ programme will enable WOMA’s clients with a host of new options. Metrics identifying dysfunctions, the supply of free services and the coordination of resources to maximise reparative action has resulted in a constructive discussion and outcome with a growing number of clients. In the ‘WOMA’s Customer First’ programme WOMA put a mirror up to them to help them make improvements. Every company has ‘blind spots’ and it takes an external viewpoint to identify them and facilitate a smart solution.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.jpg)