The ability to detect and visualize infrared energy with thermal imaging cameras has enormous benefits for users, from saving lives to saving livelihoods. Over the past decade especially, innovations in thermal imaging camera size, weight, and cost, along with upgrades to form factors, analysis software, and data processing, have made this technology invaluable in unforeseen ways.

With so many options—from unmanned aerial camera systems for search and rescue to optical gas imaging cameras for spotting fugitive emissions—it’s important to hone in on key factors when selecting the right thermal tool for your job. The question to begin with is whether qualitative or quantitative data is paramount.

Qualitative Thermography

For some applications, the operator only needs a thermograph, or infrared data represented as a visual image, to interpret the scene and identify the source of a problem or the need for a repair. This qualitative method of thermography provides the visual cue necessary to act.

Optical gas imagining is a qualitative technology that reveals gas leaks.

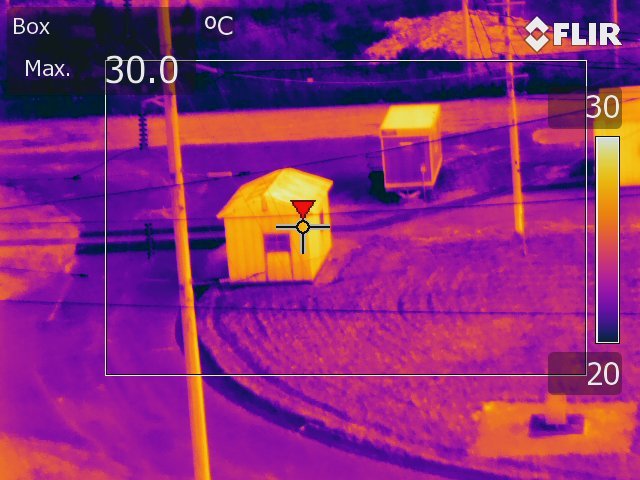

One valuable use of qualitative thermography involves search and rescue operations using a thermal camera payload attached to an unmanned aerial system (UAS). In this scenario, searchers use the camera to locate warm human shapes that stand out against a cooler landscape background. Thermal imaging is particularly useful at night or in other low visibility situations that challenge human eyes or visible-light cameras; identifying specific temperatures isn’t necessary.

That same qualitative need may also apply to advanced driver assistance systems (ADAS) or autonomous vehicles. Here the aim is similar: the ability to identify specific objects in the roadway, especially people and large animals, that drivers want to avoid in low visibility situations.

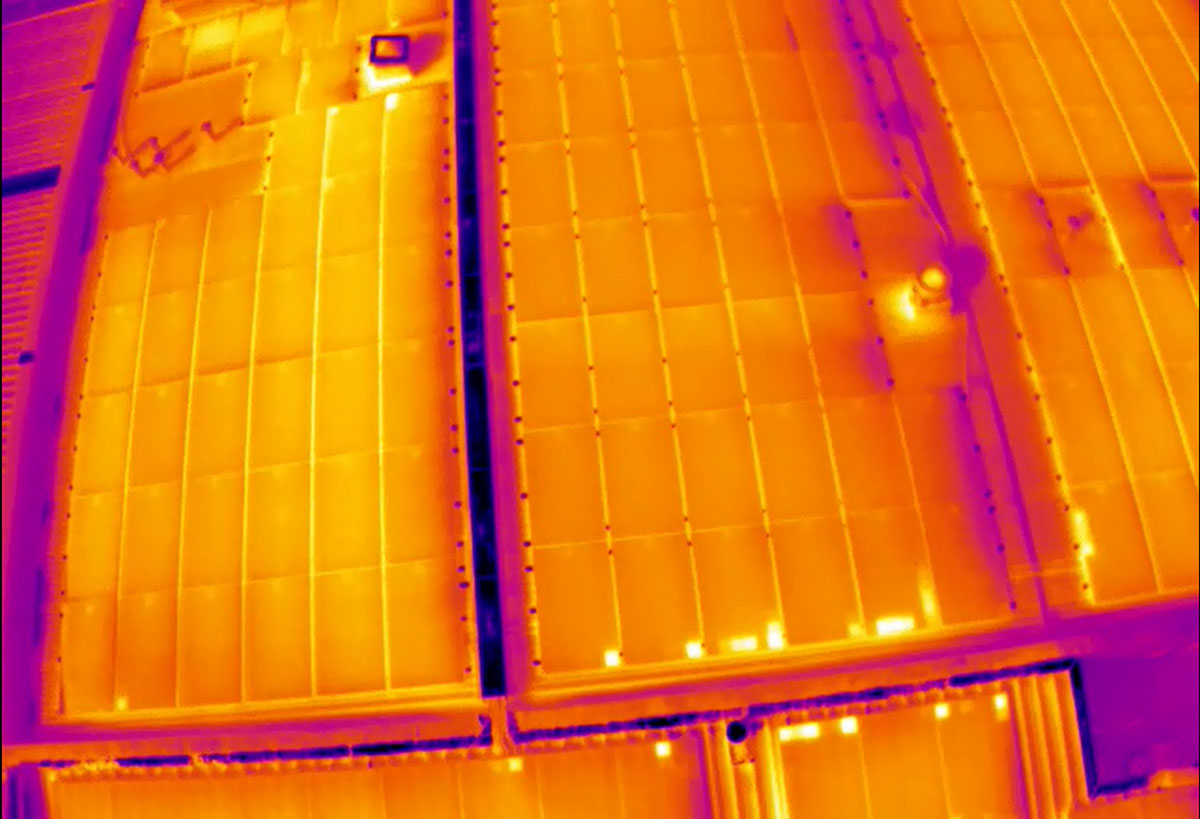

Thermal imaging drones are frequently used to spot issues in solar panels.

Quantitative Thermography

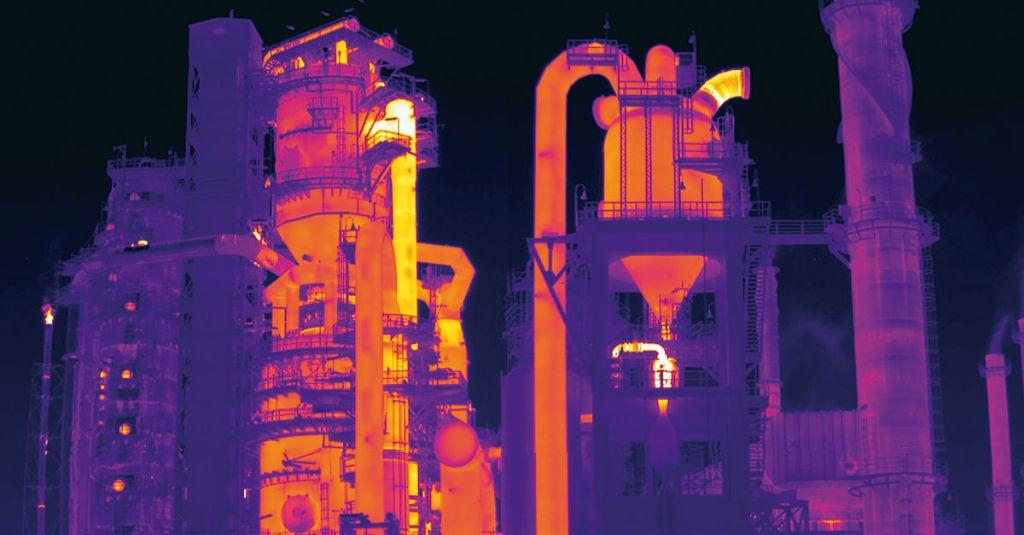

Conversely, there are times when a simple thermograph is not enough to interpret the scene. In those scenarios, the ability to detect and record the temperature of every pixel is vital to the success of the mission. In these instances, it’s important to use a radiometric thermal camera—meaning the camera is capable of measuring the temperature of a given surface by interpreting the intensity of the infrared signal reaching the camera.

With radiometric functionality in the camera, drone operators can save data for post-flight image analysis. Compatible software can accurately measure the temperatures of individual image pixels in the data, a critical process for agricultural, building diagnostic, or industrial inspection. Whether they’re looking at rooftops, solar panels, substations, or crops, drone operators can analyze the temperature data post-flight and send detailed reports and images that provide quantifiable, actionable results.

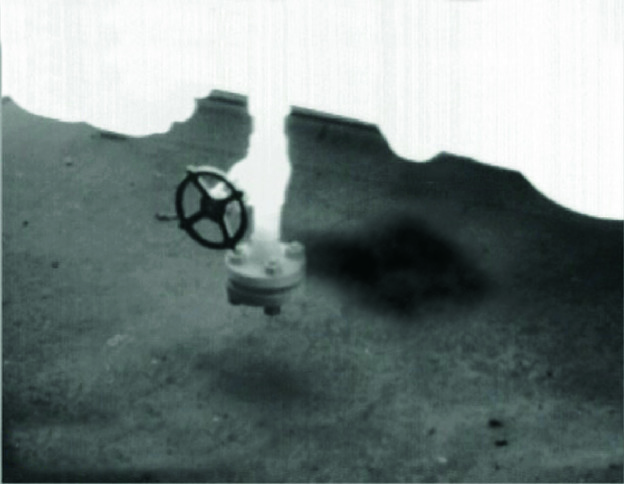

Radiometric drone data can help diagnose potential issues.

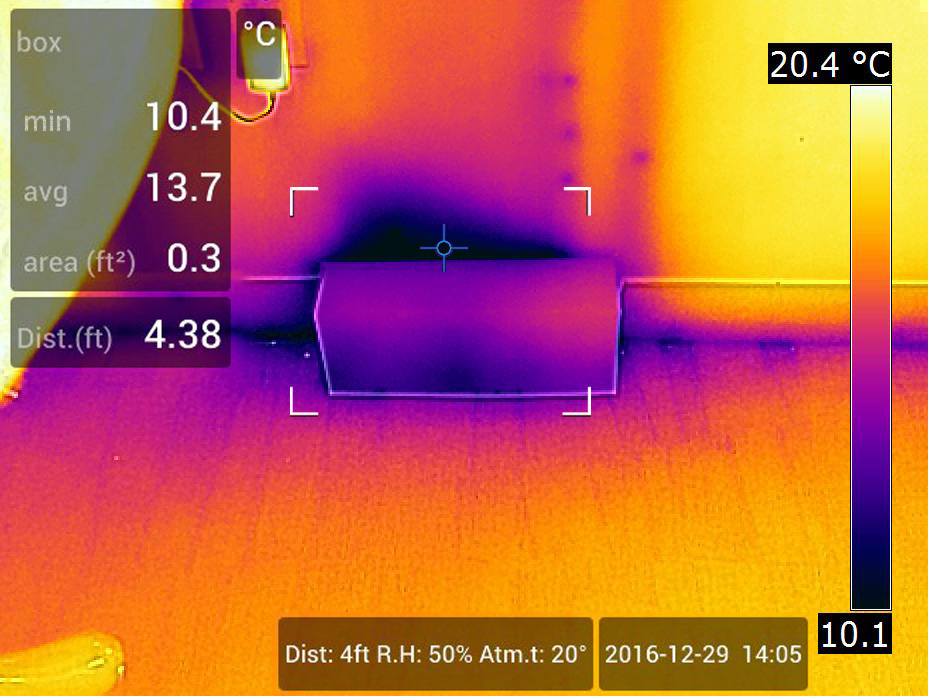

Radiometric thermal technology also plays a crucial role in condition monitoring and mechanical inspections because it can not only identify anomalous hot or cold spots but also provide the additional layer of temperature data needed to properly diagnose potential issues. These hot or cold spots may signify failure or potential failure in an electrical, mechanical, or facility-critical system; identifying these problems early allows technicians to schedule repairs or replacements without requiring a costly shut-down in operations.

Radiometric thermal cameras often include useful features such as a spot temperature meter the user can move or resize to better accommodate specific applications or multiple spot temperature meters that measure temperature ranges in different parts of the scene. This can be crucial for pinpointing the source of higher-than-normal heat that could indicate electrical, mechanical, or operational issues.

Accurate temperature data helps building inspectors make the right call.

Despite the wide-ranging use of radiometric thermography, it’s important to recognize that variance in true temperature may exist when capturing non-contact temperate data. Remote temperature sensing of a surface relies on the ability to accurately compensate for surface characteristics, atmospheric interference, and the imaging system itself. Emissivity, or the object’s ability to emit infrared, and reflectivity, or how the surface reflects infrared, can both influence and reduce the overall accuracy of the recorded temperature by two degrees Celsius or more. Most thermal imaging cameras provide compensation settings that can account for these surface characteristics and improve overall measurement accuracy.

Determining the Equipment of Choice

Although quantitative thermal imaging cameras appear to be the right choice for practically any application—as they work just as well for qualitative needs—radiometric thermal cameras are more complex and often more expensive than non-radiometric cameras. Ultimately, understanding the specific needs required will inform the appropriate choice in camera selection.

-160x160-state_article-rel-cat.jpg)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)