This is largely due to the punishing industrial process in which coffee beans are converted into soluble powder or granules. High temperatures and pressures used in the traditional instant coffee process can destroy the unique flavours inherent to beans from different regions; they also result in the roast and ground flavour associated with brewed coffee largely disappearing. The result is a product that is not as desirable to consumers as freshly brewed coffee.

Australian company Flavourtech has now developed a range of equipment to revolutionise the instant coffee process, allowing producers to lock in the taste, aroma and volatile compounds typically lost in traditional processing. Used by Ready To Drink (RTD) tea and coffee companies for over 20 years, the Integrated Extraction System (IES) now combines Flavourtech’s core technology of the Spinning Cone Column (SCC) with the Rotating Disc Column (RDC) and Centritherm® evaporator, producing a continuous, automated processing line that is ideal for instant, cold brew and RTD tea and coffee.

SPINNING CONE COLUMN

For over 35 years, the Spinning Cone Column has been used in the production of instant coffee to capture the aroma that is left after the traditional high-temperature extraction process. In Flavourtech’s new Integrated Extraction System the aroma recovery step has been positioned before the extraction process thereby protecting the coffee’s delicate aromas from extreme temperatures. For the manufacturer, the key benefit is being able to produce instant coffee that tastes like freshly brewed coffee. It is able to retain those natural and desirable coffee flavours, whether the beans are from Brazil, Colombia, Guatemala or Ethiopia.

The SCC’s distinct advantage is that it uses vacuum and steam to extract and recover volatile compounds; a gentler process than standard methods. When the aroma and high temperature extract are recombined at the end of the manufacturing process, the result is a coffee that tastes as though it has been freshly brewed, with the convenience of instant coffee. This is also true when using the IES for RTD and cold brew coffees – two of the fastest-growing beverage segments globally.

The IES is now helping manufacturers across the globe to provide premium tasting instant coffee. The IES has a small footprint, is easy to operate and is flexible in design. Not only can it be used to produce instant and RTD coffee, but the same system can be used for instant and RTD tea, maximising the possibilities for beverage manufacturers.

All this amounts to a significant step forward for the coffee industry. Instant coffee companies can now become true beverage companies with lower capital and infrastructure costs than ever before.

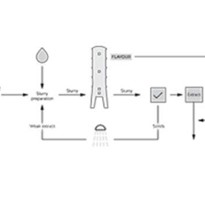

INTEGRATED EXTRACTION SYSTEM

The IES was specifically designed as a unique and revolutionary way to produce premium liquid extracts from slurries of coffee and tea.

The key steps in the IES process are:

- Roasted coffee beans are continuously fed into a slurry preparation module where they are milled to a specific size. Unlike grinders, where much of the lighter notes are lost to the atmosphere, Flavourtech’s milling system has been specifically designed to minimise flavour loss. Water is then added to create a slurry of known consistency.

- This slurry is fed to the SCC where various parameters are used to capture the desirable and valuable aroma compounds of interest. The aroma fraction is then stored in a refrigerated tank until required for addition to the concentrate prior to drying. The slurry is literally brewed within the closed SCC system in a process that takes only 25 seconds! The SCC effectively performs the dual roles of flavour and low temperature soluble-solids extraction simultaneously, thus avoiding intermediate flavour loss or degradation. The extract from the SCC is used by many RTD manufacturers to produce leading brands of canned coffee. For soluble coffee the slurry continues on to the next step.

- The de-aromatised slurry is fed into the Rotating Disc Column. The RDC is a continuous high temperature extraction column with accurate control over residence time and temperature. This process sees each coffee particle in the slurry hydrolysed and ensures an identical brewing time and extraction consistency. Furthermore, the process takes just 20 minutes, versus several hours used in traditional extraction methods. As the temperature can be varied, the manufacturer also has the ability to produce various levels of extract quality.

- Following high temperature extraction, the slurry is clarified before being sent to the evaporator for concentration. Also unique in the IES is the Centritherm® evaporator, which uses spinning cone technology with only one second heat contact time of the product at temperatures of typically 50o The Centritherm evaporator can reach concentrations higher than other evaporators allowing the concentrate to be fed to the spray dryer at higher concentrations thereby maximising capacity and flavour encapsulation.

- Finally, the desirable aroma captured in Step 2 is combined with the extract just prior to drying, thereby preserving key aromatic compounds that would otherwise have been lost in the standard extraction process.

The IES is a compact and continuous processing line that is easy to use and requires less infrastructure than traditional coffee extraction lines.

The unmatched flexibility of this modular approach means that some of the individual modules can be combined with existing processes or installed in stages. It also means that installation takes 2 to 3 weeks and the system can be installed in a single storey building with a ceiling height of just 8 metres.

The IES is the first system in the world to couple state-of-the-art flavour recovery technology, as used by international flavour houses, with the high-temperature extraction of soluble solids in a continuous process. Importantly for instant coffee producers, the IES now allows the valuable flavour of the roast coffee beans to be captured by the SCC and protected prior to high-temperature extraction taking place.

The end result: a premium instant coffee for domestic or export markets.

Beverage companies have to find ways to continuously excite consumers with coffee and tea products at both the retail and foodservice levels. Flavourtech’s technologies are giving these producers the tools they require to maintain innovation and take advantage of new opportunities while producing high quality products easily, consistently and flexibly.

STAY AHEAD OF THE PACK

Just as the proof of the pudding is in the eating, the proof of Flavourtech’s instant coffee process is in the tasting. The next step for prospective manufacturers is to conduct trials on their own roasted coffee at Flavourtech’s pilot plant facilities in Griffith, Australia.

Coffee is about to get much better; and the Flavourtech IES ensures that you will be leading the pack in producing the best, most flavoursome coffee.