As the world comes out of COVID, and production ramps up, the energy requirements of various industries will go up. However, due to unforeseen circumstances, the energy prices are also going up, unfortunately. For industries, an efficient monitoring of your energy requirements is critical. An energy meter provides is an ideal solution. In here, one can measure the various fundamental parameters such as current, voltage, power consumption. These in turn are then used to calculate the total power consumption, the total cost, and the corresponding carbon dioxide emissions. Such meters are mounted in-line in the control panels monitoring the instrument under review, and they can transmit the information remotely (via Bluetooth or Wi-Fi) to the end users. Such dynamic transfer of information is critical for the plant managers in making quick decisions for the proper functioning of the plant.

One such energy meter working for single phase load applications is shown below. This is a small compact meter mounted in an ABS flame retardant shell with dust proof wire covering. It has a thin film transistor (TFT) display This has the capability of measuring the electrical parameters and transmit it to the end user via an Android/iOS App. So, such meters can be by the end user in any energy monitoring applications.

One such application of the meter for the purposes of energy monitoring and process optimization is discussed below. The energy meter is connected inline to an electrical unit that supplies constant current to a series of electromagnetic vibrators (EMV). These EMV’s are used in the following industries

- electrostatic precipitators (ESP) for the purpose of collection of dust/fine particles/ smoke from flowing gases.

- Sugar mills for the processing of sugarcane into refined fined sugar.

- Pharmaceutical/food manufacturing units storing products in hoppers/silos.

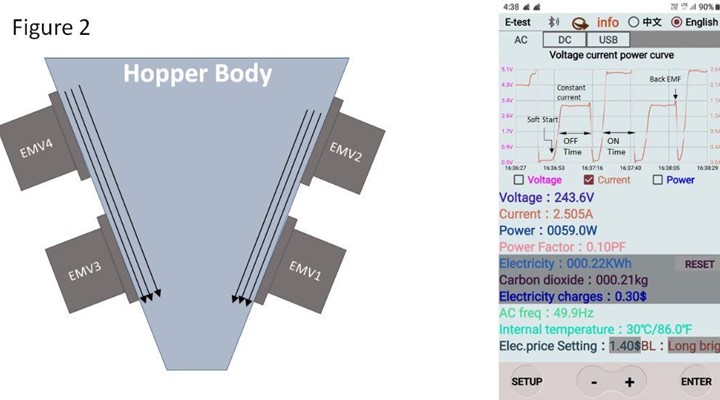

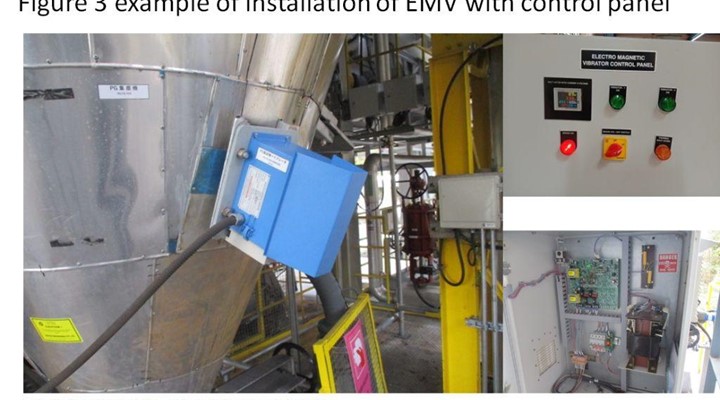

Such plants require EMV’s for dislodging the material in the hoppers. Typically, the hopper has multiple EMV attached to its side as shown in the figure. Traditionally, one applies the same amount of current to the individual EMV’s. The current generated vibrations or oscillations which in turn facilitate in dislodging the material. However, by judiciously placing the EMV’s at the top and the middle section’s of the hopper, one can run the top two EMV’s at higher current (more vibrations) and the bottom two EMV at lower current (low vibrations). In such a configuration, the material will be dislodged by the top EMV’s, and the bottom ones will need less vibrations for an uninterrupted flow. By controlling the ON/OFF timings of the vibrators, one can also switch them in the desired configuration for optimum flow of current.

The individual currents in the EMV’s are monitored by the energy meter as shown in the snapshot to the right. This image shows various critical parameters of the EMV’s such as –soft start feature, OFF/ON TIME, constant current and the minimal back electromotive force (EMF). All these features indicate that there is a synchronized power pulse(SPP) is supplied to the hopper which enables a controlled avalanche discharge(CAD) of materials.

For the plant user and manager, the availability of such information is critical by optimizing the ON/OFF Times, currents in individual EMV’s the parameters for optimal throughput can be established and then recorded daily. Furthermore, the individual state of the EMV’s i.e. is the current constant is stable and weather the back EMF is minimal can also be monitored. In Fig 3, we have shown the complete system with EMV mounted on the hopper, control panel with watt meter. So, in summary, such energy meters when combined with the appropriate instrumentation are very useful in the daily monitoring of energy needed for any industry.

-160x160-state_article-rel-cat.png)