Real-time monitoring system plays significant role during foundation pit excavation process. It will provide real-time data (such as the deformation and structural condition of foundation pit) for the operator to avoid the occurrence of any on site accident. To compare with other monitoring method, the real-time monitoring system has the advantage of strong adaptability, smaller impacts by varies weather conditions and extremely high accuracy. Sensor distribution and the choice of system model are different from varies depth and scale of the foundation pit. It is very important to choose the most suitable plan for the construction.

Monitoring system layout relay on site structure information. All sensors used should be deployed before construction. The main contents of foundation pit monitoring include the following aspects:

Foundation Pit Structure Support Monitoring

Deep horizontal displacement

Automatic inclinometer is often used to monitor the internal displacement of rock and soil, which is the most direct means to monitor the deformation of the foundation pit retaining system. It is generally arranged in the central section, the corner and the representative sections around the foundation pit. In order to truly reflect the displacement of the retaining wall and the stratum, the buried depth of the survey tube should be guaranteed.

Internal force around the retaining wall

The internal force monitoring points of the retaining wall should be arranged in the sections of the retaining wall where the extreme bending moment occurs. It is suitable to choose the midpoint of the two adjacent supports of the retaining wall and the section with larger excavation depth. In the vertical direction (monitoring section), the monitoring point should be arranged at the support and the middle part of the adjacent two layers of support.

Support the internal force

Different monitoring sensors are selected according to the type of supporting rod. For concrete support, surface strain gauge is widely used. For steel support rod, axial force gauge (also known as reaction force gauge) or surface strain gauge can both be used for monitoring point.

Anchor internal force

The internal force monitoring points of bolt should be selected in the representative position with large stress, and the monitoring points should be arranged in the middle of each side of the foundation pit, the corner and the section with complex geological conditions.

Vertical column displacement

The vertical displacement of the column (settlement or uplift) has a great influence on the axial force of the support, and there will generally be large mechanical operation or vibration around it. Dynamic level can be used to arrange monitoring points in the parts of the column with large stress and deformation and prone to differential settlement.

Lateral earth pressure around retaining wall

The lateral earth pressure monitoring points of the parapet wall should be arranged in the places with great changes in stress and soil quality or other representative parts. There should not be less than 2 monitoring points on each side of the foundation pit in plane layout.

Monitoring of surrounding structures (building settlement, tilt and crack monitoring)

Settlement Monitoring

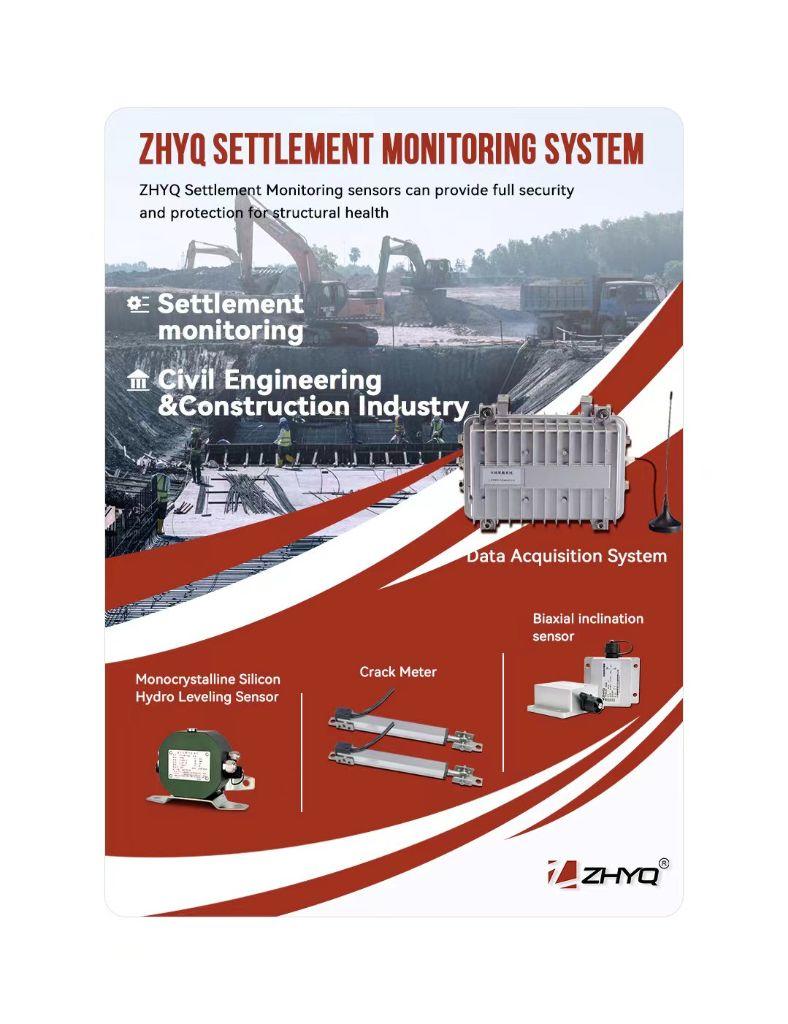

According to the survey of the surrounding buildings, determine the location and number of measuring points. ZHYQ Monocrystalline Silicon Hydro Leveling Sensor can be used in the corner, column, shape prominent sections and more sections of the two sides of the layout of measuring points, to fully reflect the uneven settlement of each part of the building as far as possible.

Slope Monitoring

ZHYQ Angle sensor can be used to arrange the building corner, deformation joints on both sides of the load-bearing column or wall.

Crack Monitoring

Representative cracks should be selected for the monitoring points of building cracks and surface cracks. When the original cracks increase or new cracks appear, monitoring points should be added in time.

Underground pipeline monitoring

Pipeline monitoring points should be set up according to the construction duration, type, material, size and current situation of pipelines. Direct monitoring points can be set up for water supply, gas, heating and other pressure pipelines. In places where direct monitoring points cannot be buried, indirect monitoring points can be arranged.

Monitoring of surrounding surface subsidence

The monitoring points of vertical surface displacement around the foundation pit should be located in the middle of the pit edge or other representative parts according to the monitoring section.

Other monitoring

Porewater pressure

ZHYQ osmometer can monitor the seepage water pressure inside the foundation pit. It is generally placed in the representative parts of the foundation pit with large stress and deformation.

The underground water levels

Foundation pit groundwater level monitoring is to monitor the impact of precipitation on the surrounding environment. The water level meter should be arranged along the periphery of the foundation pit and the protected object or between the foundation pit and the protected object, such as the water level monitoring points of adjacent buildings, important pipelines or densely populated areas of pipelines.

To sum up, in the foundation pit engineering structure safety monitoring system, mainly for stress/strain of the foundation pit, settlement, displacement and other parameters, can be used to this kind of various types of sensors and equipment monitoring project, different models, so when making sensor equipment selection should consider mainly range, sensitivity, precision and working environment factors, for the convenience of management at the same time, ZHYQ uses the system monitoring centre to implement a unified and centralized management of all front-end sensor equipment, IOT gateway, data acquisition equipment and IOT monitoring cloud platform.