The Project

CHEP Australia were constructing a new pallet remanufacturing plant in Dandenong, Victoria. Part of this re-manufacturing process was an automated pallet inspection system to determine and classify the damage on incoming pallets.

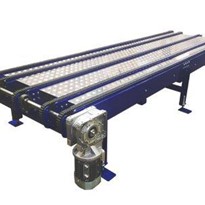

The conveyors had to have the following attributes:

- Operate smoothly ensuring effective transfer of pallets from conveyor to make sure of pallet alignment;

- Very heavy duty conveyors required to withstand large impact loads and the demanding operating environment (the customer having had previous problems with lighter weight construction conveyors bending and warping, causing operational problems and costly down-time);

- Conveyor had to operate at 45+ metres per minute to meet the production output;

- It was a requirement of the project that full technical documentation was provided for the project. This included all manufacturing drawings, consumable lists and operating instructions.

The Result

Australis Engineering provided a customised conveyor solution that minimises plant down time, operates at high speed and is made of a very heavy duty construction to ensure a longer equipment lifespan to further reduce lost production and reduce operational costs.

Australis provided the following outcomes:

- Design, and manufacture of five, 5.3 metre powered belt conveyors to handle damaged pallets at a high speed of 45 metres per minute,

- Two of the conveyors incorporated a special cantilevered conveyor design with small diameter end rollers to incorporate the automated pallet inspection system underneath.

Conveyor features include:

- Use of heavy-duty conveyor profile utilising structural steel sections;

- Large diameter rollers for high strength and ability to withstand impact loads of high speed pallets;

- The use of a specialty belt material to withstand damage from nails and broken pallets.

Innovation

A key element of the Australis Engineering solution has been the use of the heavy-duty construction and special belt material, combined with the ease of installation of conveyors. This has allowed the conveyors to quickly and smoothly convey the heavy, damaged pallets at high speed.

-160x160-state_article-rel-cat.png)