Icon Equipment solutions for Label Machines

Label machines are crucial components in the packaging and production process, ensuring that products are accurately labelled, meet regulatory standards, and are ready for market. Understanding the different types of labelling machines can help businesses choose the right equipment for their specific needs. Icon Equipment International offers a variety of labelling machines tailored to different applications.

1. Semi-Automatic Labelling Machines

Semi-automatic labelling machines are designed to handle lower to moderate production volumes with greater flexibility. These machines require manual intervention for some tasks, such as placing the product on the conveyor or adjusting the labels. They are ideal for businesses that need a cost-effective labelling solution without the complexity of fully automated systems. typically operate at speeds of up to 30 bpm.

2. Inline labelling machine

Inline labelling machines are built for high-speed production lines where efficiency and accuracy are crucial. These machines apply labels as products move along a conveyor, making them ideal for continuous production environments. Our inline labelling machines can handle a variety of product shapes and sizes, including round and rectangular containers, tapered items, and products requiring labels on both sides. They are versatile and widely used in industries such as food and beverages, cosmetics, and pharmaceuticals.

Our Inline vacuum labelling machines, designed and built here in our factory in Melbourne, use a combination of vacuum technology and advanced dispensing mechanisms to ensure precise and efficient label application. The vacuum system stabilizes and positions the label, preventing movement, creases and ensuring accurate label placement even at high speeds.

They are highly versatile, accommodating a variety of shapes and sizes, including round, oval, rectangular, and tapered containers.

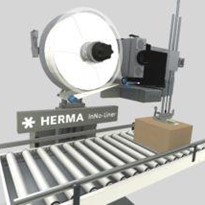

3. Box Labellers

Box labellers can apply labels to different parts of a box, including the top, bottom, or both sides. This versatility is essential for ensuring that products are labelled correctly, regardless of how the box is oriented on the shelf or in storage.

4. Print and Apply Labellers

Print and apply labellers combine printing and labelling into a single operation. These systems print variable information (such as barcodes or expiry dates) directly onto the label before applying it to the product. This integration improves accuracy and efficiency, particularly in environments where product information changes frequently. ICON box labellers are designed and built here in our factory in Melbourne. Contact us for a quote.

5. High-Speed Rotary Labellers

High-speed rotary labellers are sophisticated machines designed to meet the demands of high-volume production environments. They use a rotary mechanism to apply labels to products efficiently and accurately. These labellers are particularly suited for industries where continuous operation and rapid throughput are critical, such as in the beverage, food, and pharmaceutical sectors.

The rotary labeller features a rotating carousel or turret that holds multiple label heads. As the carousel spins, it moves containers through different stations where labels are applied. The rotation allows for a consistent and high-speed application process, with each container receiving a label as it passes through the labelling stations.

High-speed rotary labellers can achieve speeds of up to 1,200 containers per minute, depending on the specific model and the size and shape of the containers. This high throughput makes them ideal for industries with large-scale production needs.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)