Microbial growth due to contaminated water or ingredients can cause discolouration, off flavours and shortened shelf-life. The threat of contamination is further increased as manufacturers respond to demands for less chemical additives and preservatives.

Effective microbial disinfection of the whole process is therefore essential. UV treatment of water is ideal for the food & beverage industries.

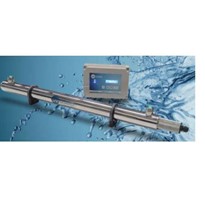

A non-chemical disinfection method which is gaining increasing acceptance is UV treatment of water. UV treatment of water kills all known spoilage microorganisms, including bacteria, viruses, yeasts and moulds (and their spores). It is a low maintenance, environmentally friendly technology which eliminates the need for chemical treatment while ensuring high levels of disinfection.

Benefits of UV Treatment of Water

UV treatment of water has many advantages over alternative methods. Unlike chemical treatment, UV treatment of water does not introduce toxins or residues into process water and does not alter the chemical composition, taste, odour or pH of the fluid being disinfected.

UV treatment of water can be used for primary water disinfection or as a back-up for other water purification methods such as carbon filtration, reverse osmosis or pasteurisation. As UV treatment of water has no residual effect, the best position for a treatment system is immediately prior to the point of use. This ensures incoming microbiological contaminants are destroyed and there is a minimal chance of post-treatment contamination.

UV treatment of water applications in the food and beverage industries

- Direct contact water

Although municipal water supplies are normally free from harmful or pathogenic microorganisms, this should not be assumed. In addition, water from private sources such as natural springs or boreholes could also be contaminated. Any water used as an ingredient in food or beverage products, or coming in direct contact with the product, can therefore be a source of contamination. UV treatment of water disinfects this water without chemicals or pasteurisation. It also allows the re-use of process water, saving money and improving productivity without risking the quality of the product.

- CIP (Clean-in-Place) rinse water

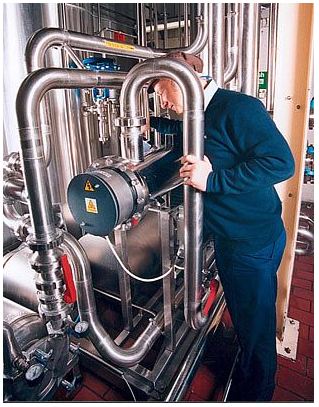

It is essential that the CIP final rinse water used to flush out foreign matter and disinfecting solutions is microbiologically safe. Fully automated UV treatment of water can be integrated with CIP rinse cycles to ensure final rinse water does not reintroduce microbiological contaminants. Because of their mechanical strength, MP lamps are not affected by any sudden changes in the temperature of the CIP water.

- Filter disinfection

Stored reverse osmosis (RO) and granular activated carbon (GAC) filtrate is often used to filter process water, but can be a breeding ground for bacteria. UV treatment of water is an effective way of disinfecting both stored RO and GAC filtered water and has been used in the process industries for many years.

- Dechlorination

GAC filters are also often used to dechlorinate process water, removing the ‘off’ flavours often associated with chlorine disinfection, meaning the flavour of the final product remains untainted and free from unwanted flavours or odours. UV treatment of water ahead of GAC filters used for dechlorination improves the performance of the filters and results in longer carbon runs, so decreasing operating costs.

- Sugar syrups

Sugar syrups can be a prime breeding ground for microorganisms. Although syrups with a very high sugar content do not support microbial growth, any dormant spores may become active after the syrup has been diluted. UV treatment of water , both syrup and dilution water prior to use will ensure any dormant microorganisms are deactivated.

- Tank head space disinfection

UV treatment of water can be used to disinfect displacement air for pressuring tanks or pipelines holding perishable fluids. Storage tanks are particularly susceptible to bacterial colonisation and contamination by air-borne spores. To prevent this, immersible ultraviolet disinfection treatment systems have been designed to fit in the tank head air space and disinfect the air present.

- UV treatment of wastewater

Effluent from beverage manufacturing facilities can be treated without the use of environmentally hazardous chemicals. This ensures all discharges meet with local environmental regulations. As already mentioned, because process water can be treated and re-used with the UV treatment of water this also leads to a significant reduction in the amount of waste water produced.

Read the complete article and to subscribe to the Hanovia RSS News Feed by visiting the Hanovia News Blog