With transport often a key component of consumer item distribution, ICA’s

specialised design engineers design and manufacture as well as implement loading and unloading facilities at two or more sites, according to client requirements.

Whether it is food and beverage product, clothing and shoes, or any other

consumer line of stock, ICA’s solutions are normally based around a system that is able to pre-arrange product to conform to transportation requirements and load/unload palletised product in an efficient and reliable way.

In addition, the tailored outcome will also reduce time and handling costs

associated with existing/standard practices.

What also is taken into account is that the warehouses will often be serving all types of businesses with huge variations in delivery quantities: ranging from the largest supermarket and retail chains down to the local grocery and general stores.

Managing director of ICA, Mr Don Erskine, says until recently many potential clients would most likely have approached a foreign company to design,

manufacture and implement such a sophisticated system as leading materials handling suppliers in Australia had lost pace with world’s best practice.

"What works in our favour is that we are an all Australian company, based in Australia, that can deliver a rapid turnkey result," said Mr Erskine.

"By being local, we are able to significantly reduce the turnaround time

compared to what an offshore supplier could deliver.

"We are able to deliver on time and on budget a modern and materials handling systems coordinated across two or more high-volume sites that can work in synchronicity to facilitate a rapid and constant product-to-market demand."

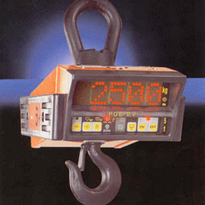

One of the key requirements when unifying multi-site operation is to reduce handling associated with trailer loading and unloading to and from production and storage facilities.

"This is a critical issue,” said Mr Erskine. “The less handling, the better the

return per truck trip, and when it is taken into consideration that two or more

depots have the capacity to load and unload on a 24/7 basis, over the course of each financial year the client will see very significant returns.

"The idea is to automate docks so virtually no handling is involved. The use of expensive forklifts is obsolete as a mechanism performs all the loading and unloading, thereby eliminating all occupational health and safety issues associated with manual handling.

"Software links all depots in real-time so that plant management is kept

constantly up-to-date with quantities of product movement."

As an example of its unifying solutions, for one beverage client ICA designed, manufactured and implemented two types of docks - Route Docks and General Docks - to meet schedules servicing local small businesses as well as

supermarket chains.

Route Docks operate using a specially designed air skate system that engages with a specialised flat-floor trailer configuration with inbuilt air guide rails for the loading of product.

With the General Docks, a chain conveyor system combined with an air

operated powered chain floor trailer facilitates both loading and unloading of product.

The docks receive product from an automated conveyor-driven delivery system that rapidly forms the pallets into complete pre-arranged trailer loads, allowing trailers to be loaded in a turnaround time of 2-3 minutes.

"This is exceptionally productive as the pre-arranged forming of a complete

load actually takes place before the transport vehicle has arrived to collect the load,” said Mr Erskine.

"This system is infinitely faster than the archaic method of reversing an empty truck into the dock, using expensive and potentially dangerous forklifts to load the truck pallet by pallet, then checking off the paperwork before delivery starts.