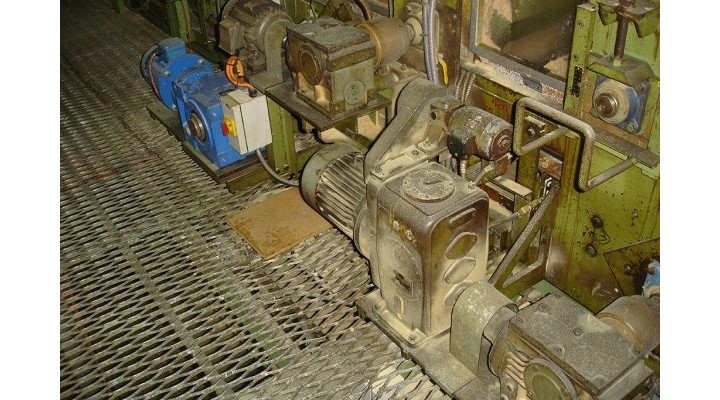

Their Gympie site in Queensland needed to overcome an existing problem with some existing right-angle worm drives on their particle board press.

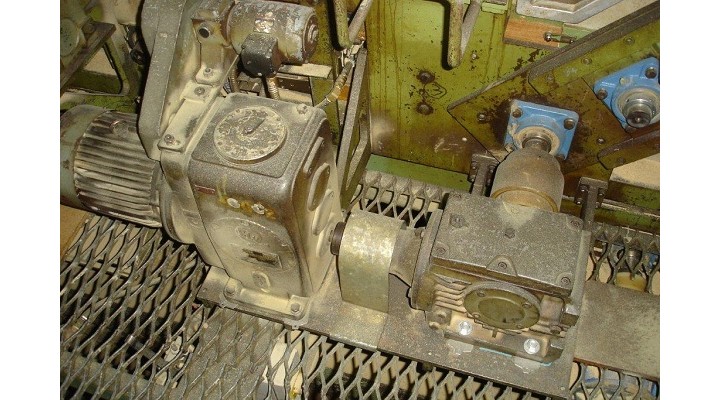

The problem with the worm drives was they were no longer commercially available. This meant CHH needed to continually repair the units which was an expensive process as the units required new gearing and spare parts that were manufactured as "one offs" by outside suppliers. Added to this, the existing units were a combination of an inline gearbox, fitted to a right angled worm gearbox which was very large, bulky and inefficient.

Solution:

Working with the local Sumitomo sales representative from the Sumitomo Brisbane office, a proposal was put forward to CHH to replace the existing setup with a Sumitomo Buddybox.

The Sumitomo Buddybox offered the following features:

- Utilises the Cyclo Advantage on the input side of the gearbox and thus offering a 300 per cent shock load capacity

- Has a common output bevel set for the complete Buddybox range for all common Buddybox sizes; less spares are required to be held on the shelf, as one set fits all units

- Local stock and technical support

- More compact in size and lower shaft height, meaning to replace only required a simply manufactured base plate

- More cost effective than repair of existing units

- Long running life, meaning that once they changed the units out, it was only a matter of standard regular maintenance

- A much more efficient unit, meaning lower electricity costs and a "cooler" running motor

Outcome:

CHH found the change out of the units to be very simple and once the unit was changed out, stopped the continual overhaul and repair of the old units.

Additionally they found that the electric motor was actually drawing less current which equated to power savings on the initial change over. They were convinced this was the way forward and proceeded to change out a further nine units.

They have since started doing similar change outs, on other parts of their plant, utilising the Sumitomo Buddybox along with the local Sumitomo Engineering support and stock holdings.

To view further Sumitomo products, please click here