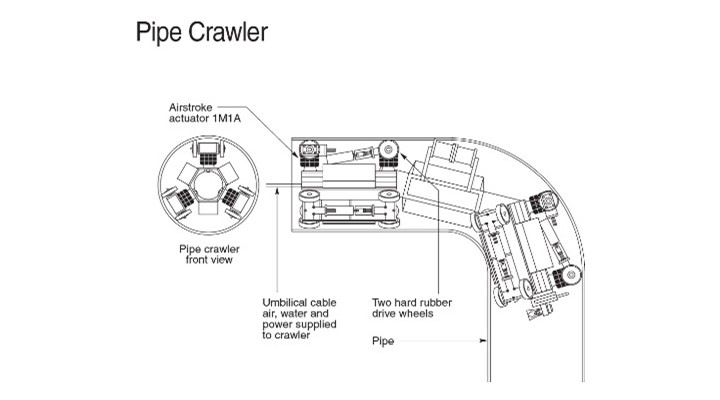

Airstrokes operate without seals, shafts or internal moving parts to provide ultra-reliable actuation alternatives for materials handling technology exposed to grime, debris and waste, which can disrupt the seals and shafts of convention pneumatic and hydraulic cylinders.

The globally proven Airstroke range offers actuation strokes ranging from 12.5mm for the tiny (16mm high deflated) Airomatic™ polyactuator types typically used on conveyors, through to single, double and triple convoluted models with strokes of more than 300mm used as both actuators and isolators across industries extending from mining and energy, oil and gas to manufacturing to food and beverage processing applications requiring clean actuators that don't need lubrication and can cope effortlessly with high-repetition tasks.

Eliminating lubrication eliminates another sticky surface for waste adherence. Another advantage of this form of actuation is the inherent flexibility of the actuators when they meet their working surface.

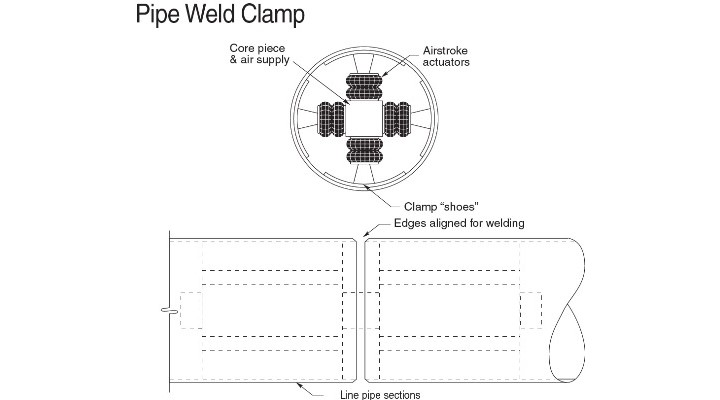

Being made of rubber and not having any rods or seals to damage, they can bend or flex to the surface of belts, pipelines or conveyor sections, for example:

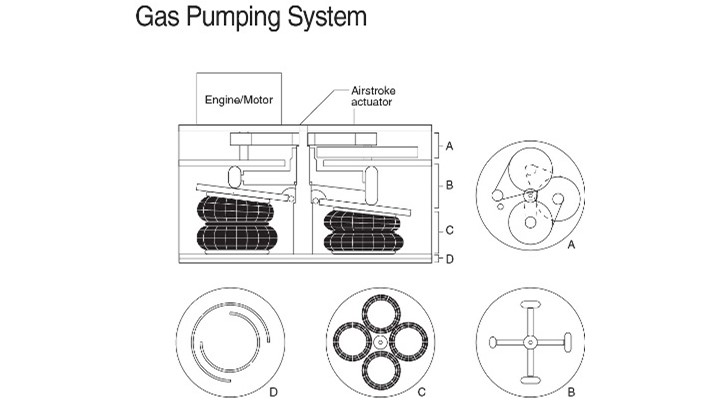

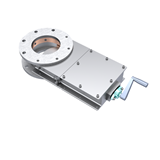

Airstrokes can be incorporated into (from top to bottom in images left) pipe crawlers, gas pumping systems, and pipe weld clamps.

Their flexibility also makes them ideal for applications such as belt takeups or roller friction applications, where they may be applied against an oscillating surface. Airstrokes are used for lift gates, drive tables, transfer sections, belt tensioners, belt centering guides, waste scrapers and friction brakes.

The enormously tough rubber and fabric actuators - in effect, balloons or bellows engineered to particular shapes for particular tasks - are manufactured by Firestone in exactly the same way as the air springs used as suspension springs in heavy vehicles such as semi-trailers.

They can also stroke through a radius without a clevis, thus eliminating both complexity and cost when engineers need to actuate through an angle. Their ability to soak up shock without damage while delivering high-repetition strokes means they are highly applicable to engineering applications ranging from stamping and clamping to pumps and conveyors.

Air Springs Supply national marketing manager James Maslin says: "We don't say for a moment that Airstrokes are the ideal solution for all actuation needs, because every professional knows that each case needs to be considered on its own special needs. But we do know from a generation of experience that they can save a lot of time and money over a vast range of applications, because we have installations that have completed millions upon millions of cycles with outstanding reliability."

"If safety, reliability, flexibility and repetition are engineering issues, then they can be extremely viable and economic alternatives."