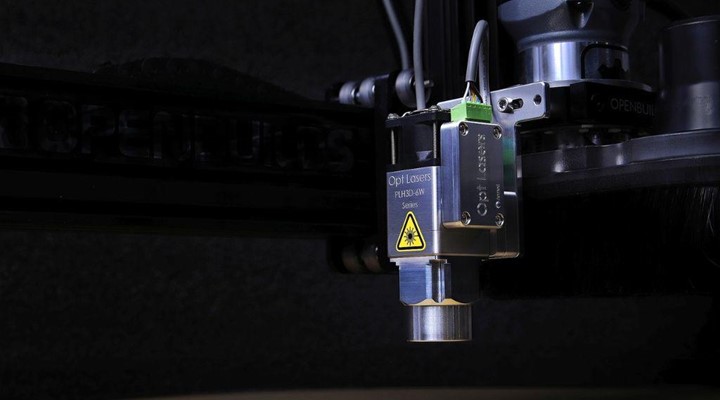

WHAT IS RAPID PROTOTYPING?

Rapid or 3D prototyping is the process of fabricating a part repeatedly with minor adjustments in between until a final prototype is achieved. These adjustments are made using the appropriate software and include dimensional, aesthetic or mechanical changes.

Although 3D printing is the most common choice for rapid prototyping, as the method has gained popularity it now encompasses other technologies, such as laser cutting and CNC milling.

THE BENEFITS

Rapid prototyping has grown in popularity, especially over recent years, due to the number of benefits it provides to the research and development stages of production.

One major benefit of 3D prototyping is that you are able to create higher functioning prototypes earlier on in the design phase, speeding up the process. This also allows businesses to find and adjust any mistakes or weaknesses quickly and easily.

Another advantage of rapid prototyping gained by the quicker process is that businesses no longer have to spend as much time and money on the whole operation. This is especially true when you add the financial benefits that 3D printing provides on its own.

HOW DOES INNOVEC USE IT?

At Innovec Controls we utilise our experienced engineering department to create custom designed instrument housings for your application.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)