Not everyone has heard about the Australian Packaging Covenant (APC), but it is an ongoing commitment between Industry and Governments regarding sustainable packaging initiatives. Their initiatives aim to change business culture to design more sustainable packaging, increase their recycling and reduce packaging litter. (Go to their website regarding their 5 year plan). So specifically relating to plastic what are some of the initiatives currently happening in Australia?

In Australian households most people are able to recycle plastic bottles and other hard plastics within their local council recycling program, but not soft plastics like shopping bags as this jams their sorting machines. One of the more recent initiatives has closed the plastics gap by allowing people to recycle their soft/flexible plastics - shopping bags or anything that can be scrunched up. REDcycle (an Australian company) has teamed up with other Australian companies like Coles and Woolworths and is providing REDcycle bins so households can deposit their soft plastics.

For Australian businesses there are a number of Australlian companies accepting commercial plastic waste. Polytrade Recycling and Suez Australia are just two examples.

So what kinds are things are these companies producing with their recycled plastics? Companies like Replas are creating durable, high quality and attractive products like:

- Outdoor seating - park benches, table and chair settings in playgrounds and schools

- Bollards

- Decking

- Exercise Equipment - commonly seen in parks and other community spaces

- Fencing

- Signage and much more

So what else can we do?

In terms of encompassing the values of reduce, re-use and recycle:

- Get Packed for example, keeps the plastic wrap that comes on pallets that come into our store, and any bubble wrap scraps and uses it as void fillers in packages that we send out. We don't throw it out for landfill. It saves the environment as well as money.

- Consider recycled plastic products instead of wooden products. This will not only save a tree, but ensure demand for the goods that are made and make the whole process viable.

- Really consider your choice of packaging, how it's been created and how can you encompass the values of reduce, reuse and recycle.

Packaging Products - RRR - a few examples

Reduce

- Pre-stretched pallet wrap - As this stretch wrap has been pre-stretched not only does it require less pulling by the handler, it means substantially less plastic wrap is required for the same job.

- Cryovac CT Shrink Film - an ultra thin high performance shrink film resulting in less plastic being used

ReUse

- HSM Cardboard Perforator/Shredder - Re-use cardboard cartons that come into your business and instead of tossing them, create your own protective packaging material. The HSM Cardboard perforator will perforate your cartons and create attractive padded packaging which is also degradable.

- Shurtuff Round Trip Courier Bags - If you're an on-line retailer then sometimes your customers have to return items (wrong size, wrong choice). A Round Trip Courier bag means the customer can re-use the bags the items were delivered in, whilst still ensuring security of the items.

Recycle

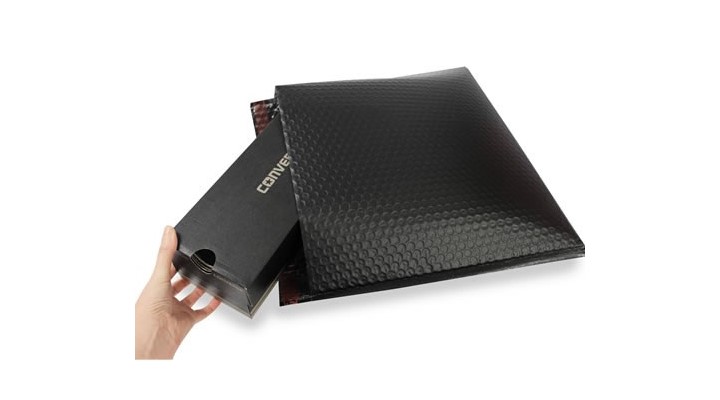

- Armour Padded Mailer Bags - Black or White - have been made from up to 15% recycled content.

- Jiffy Padded kraft paper mailers - These are a strong, heavy duty kraft paper envelope made with 100% recycled paper fibre cushioning protection.