Frequently, the source of the problem is improper curing in relation to climactic conditions.

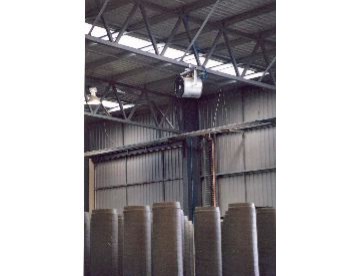

Air movement specialist, Fanquip, with the recent introduction of its 'Hydroblast' system, has added a simpler, more effective control to this procedure.

The company points to technical documentation from the Cement Concrete and Aggregates Australia (CCAA) that outlines best practice and is well known by companies involved with concrete, but escapes those newer to the market, who are more likely to make mistakes.

In the public domain are guidelines detailing how concrete is cured by the application of extra water to the surface of the concrete, or stopping water loss from the concrete.

The objective of curing is to ensure the concrete is less likely to crack, is more durable and has a surface that wears better, lasts longer and better protects any steel reinforcement to ultimately make a product stronger to carry more weight without breaking.

Curing is done just after finishing the concrete surface, as soon as possible so it will not be damaged.

As curing is relative to the rate at which water transpires from the concrete, the message is the slower the transpiration of water from the concrete the mixture is better controlled and the better the quality of the cured concrete.

By keeping concrete moist, the bond between the paste and the aggregates gets stronger. Concrete doesn't harden properly if it is left to dry out - cracks and instability plague the final product.

CCAA documents state the simplest method of applying water is to put a continuous fine, misty spray of water over the concrete. The warning is clearly made that the spray must be a very fine mist or else it will damage the surface of the concrete.

Fanquip says industry needs to be especially mindful of this in a country like Australia, which has varied temperature ranges across the continent and adjustments to timing and moisture control must be made according to local conditions.

The company points that concrete will dry out more quickly in hot weather in the very north of the country compared to what would be experienced along the southern seaboard.

It was partly with this in mind and the fact that concrete and cement is playing an increasing part in product manufacture that saw the company introduce the 'Hydroblast' system to provide correct, controlled curing rates.

By combining its durable Mancooler fans with a 'Hydroblast' attachment, the company has provided a fast, efficient control.

Hydroblast emits a fine mist directed by the Mancooler air stream to hydrate concrete at an exact rate as it cures. This process is far more efficient than longstanding 'wetting-down' techniques using hoses.

During the critical curing process, the rate of moisture dissipation is crucial, and this is where Hydroblast comes into its own.

Hydroblast is manually set to emit a 'hydromist' at a precise rate relative to the surrounding air temperature and atmospheric humidity on a given day, thereby providing optimum water dissipation from the concrete as it dries.

The system can be applied indoors or outdoors. For outdoor use, water density can be increased to counter strong wind conditions, therefore ensuring not only does the water land on its intended target (the slab), it also offsets the superfluous drying rates common in windy conditions.

Hydroblast is also scalable. This means regardless of whether contractors are dealing with small or large volumes of concrete, no excess energy is being consumed. The quantity of fans and water is relative to the project at hand.

Space efficiency and transportability is also a major attribute. In tight construction spaces, each Mancooler unit that hosts the Hydroblast system is easily wheeled in through normal 820mm doorways.

In all conditions, operators have rigid control of the degree of humidity in the working environment as the water dispensation quantity can be controlled in sync with air current rate.

Hydroblast is an attachment system that emits a very fine water vapour to quickly control moisture. The area in question can be quite an open site, but because a water mist controls the permeation of the cooling effect, that slight density of the water allows it to function in a non-sealed environment.

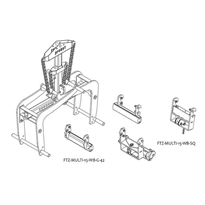

The entire Hydroblast kit includes a mist ring, nozzles, a shut off valve, filter, mounting brackets and installation instructions.

Mancooler fans are powerful yet lightweight and portable so they can be positioned and relocated with ease.

Fanquip uses a tough, industrial coating on its products ensuring they last more than 15 years in the harsh conditions of factories and foundries all over Australia.