E2.1 series e-chains for small and medium sizes reduce noise by 10 dB and assembly time by 50%

Whether linear or vertical travels, torsions or rotations - energy supply with polymer e-chains has hardly any limits today. And the potential is far from being exhausted: new polymer materials, improved designs and customer-specific requirements are continually expanding the product range. This is also shown by the advanced E2.1, the e-chain standard for the small and medium load range.

In the 1970s, igus GmbH was one of the first companies to manufacture polymer energy chains for industrial applications. The products were listed on a double page at that time, but the catalogue now includes over 1,300 pages with 90,000 types of chains, all available from Treotham. This means that igus now has the largest selection of energy chains for moving applications. The offer ranges from 3D robot chains and micro-e-chains with the smallest inner heights and bend radii up to universally applicable all-rounder chains as a comprehensive modular system for individual assembly. From the start, the e-chains have continuously developed: on the one hand, mechanically and constructively, which made longer unsupported lengths, more additional loads and longer travels as well as movements in all directions possible; on the other hand, research and development of new materials have made the igus energy chains lighter and quieter. Furthermore, the energy chain has become more and more differentiated in terms of its use: in its range, igus has special chains for use in cleanrooms and the food industry, for the wood industry, for offshore, crane systems or agriculture. In the meantime, as smart plastics the e-chain has even become intelligent and enables predictive maintenance. However, the basic idea of developing reliable machine elements that extend the service life of machines and systems while reducing costs has remained to this day.

E2.1: igus e-chain standard for small and medium sizes

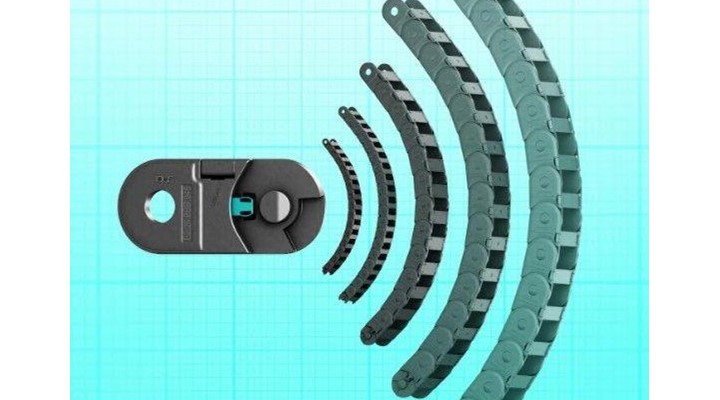

The E2.1 is an all-rounder for small and medium-sized loads. This new generation of the two-piece energy chains was developed to improve on the preceding E2/000 series, which has proved its worth for over 15 years. The E2.1 series offers extremely fast filling of the e-chain from the side or from the top – along the inner or outer radius, using a chain opener or screwdriver. In this way, 1 metre of the energy chain can be opened in just 2 seconds. Due to these features, the E2.1 is ideal for use in general engineering, woodworking and metalworking industries, and in machine tool construction. In addition to an inner height of 10, 15 and 26 millimetres, users can also have inner heights of 38 and 48 millimetres. The customer will have the opportunity to put together the solution that suits them best from over 850 different chain combinations", explains Jörg Ottersbach, Head of e-chains division at igus. A special design feature of the new E2.1 is the unique lens-shaped brake at the stop-dog of the chain links. This ensures a particularly quiet chain travel with low vibration and noise. Compared to the previous generation, the noise is reduced by up to 10 dB thanks to this innovative brake design. The E2.1 series is up to 15 dB quieter than comparable energy chains on the market. This was proven by tests at 2m/s in an insulated sound chamber at the 2,750 square metre igus test laboratory.

Custom-fit energy supply thanks to maximum flexibility

In addition, the E2.1 has an optimised interior, which offers even more space with the same outer height when compared to the E2/000. To match the design of the interior of the chain, igus offers a complete interior separation range consisting of lean separators with rounded edges for a long service life of hoses and cables. The assembly of the interior separation with lean separators is up to 50% faster than previous solutions, therefore ensuring even faster harnessing. For side-mounted applications there are notch separators that ensure a custom-fit. The notch separator engages in a narrow integrated grid in the crossbar and guarantees a secure fit. This means that it is now very easy to insert shelves on several levels for interior separation, as needed. The opening mechanism of the crossbars along the inner and outer radii guarantees fast filling with cables and hoses. These captive crossbars, which can be opened with a screwdriver, can be pivoted open to 115 degrees and latched into their final position. If necessary, they can even be removed completely, fitted again and closed by just pressing down. The rounded edges of the crossbars and separators of the chain also ensure a long service life of hoses and cables. Notches and a positioning scale enable optimum separation of the energy chain. With matching highly flexible chainflex cables and connectors, the E2.1 is available as a complete, ready-to-connect energy solution called "readychain" for all mechanical engineers worldwide.

Assembly instructions easily explained thanks to the QR code

The E2.1 is also equipped with a QR code. This connection of the "offline" and "online" worlds has a very tangible benefit for the machine builder: faster information, easier assembly and spare part procurement via the Internet. To use the code, the engineer uses a smart phone or tablet camera to scan the QR-codes, which are located on the crossbars and side parts. The engineer is directed to the online portal, where igus provides all the important information about the product. These include photos and videos that show the engineer assembly instructions. Important assembly steps are shown in slow motion for better understanding. This helps engineers reduce set-up times and simplify initial installation. The QR-code also simplifies the process for ordering spare parts for energy chains. Intuitive illustrations on the website help the engineer to understand the structure of the igus part numbers and to recognise the different components.

Quickly openable and nevertheless tight: swarf-repellent e-tubes

In addition to the E2.1 product range, these e-chains are also available as enclosed energy tubes in the R2.1 range, which has the same design features as the E2.1. The swarf-resistant, stable e-tubes are available in 26, 40, 48 and 75mm inner height. They are primarily of interest in the construction of machine tools, as a reliable energy supply is often required in the swarf area. This industry is faced with the enormous challenge of mastering the increasing pressure of prices combined with rapidly growing technical requirements. During the swarf test, it was shown that the tubes of the R2.1 series are among the tightest energy tubes on the market. During this laboratory test, the tube is moved continuously in a swarf drum filled with two kilograms of metal swarf of very different sizes and shapes. After 100,000 cycles, the size 40 e-tube R2.1 let only 0.5 grams of swarf accumulate inside.

All energy chains and other igus products are available from Treotham Automation.

About Treotham:

Treotham Automation is a leading supplier of high-quality electrical components and products to a wide range of industrial markets. Being the distributor for many world leading suppliers in their respective fields, Treotham Automation offers a diverse range of products to a variety of industries. With multiple warehouses and experienced staff, Treotham Automation strives to provide customers with a total solution, with the highest quality products, the best service and ongoing technical support. For more information, visit www.treotham.com.au

-160x160-state_article-rel-cat.jpg)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)