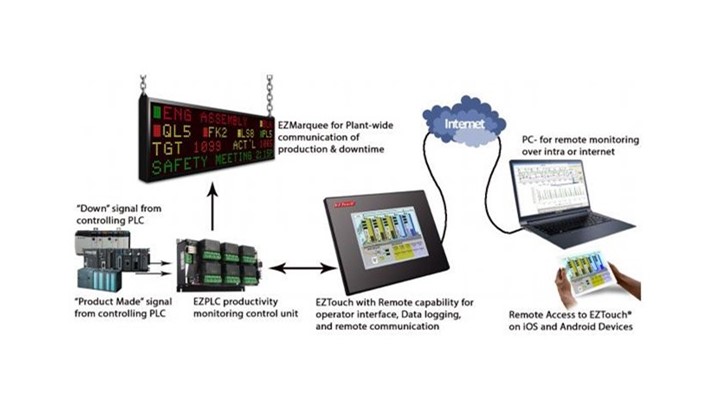

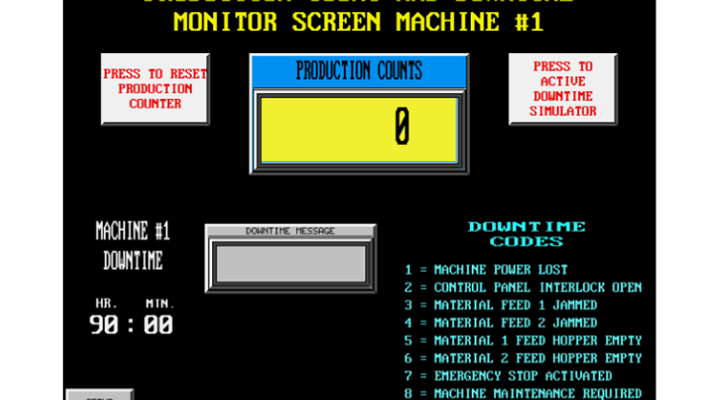

This system monitors production count and machine downtime. It also consists of an EZPLC working as a black box productivity monitoring control unit the EZMarquee, and a EZTouch HMI with built-in Remote Capability. The EZPLC gets machine down signal from a machine controller PLC. Operator is then prompted to enter a code indicating reason for machine being down. This code and time is retained in the history. In addition the productivity monitoring control unit tracks the time that the machine remains down. Production count, downtime and the reason code are displayed on the EZMarquee.

In this demonstration, we assume that the existing controlling PLC in the plant provides two discrete signals. One to indicate that a part is made, two to indicate the machine is down. For each “Product made” signal, the production counter is updated in the EZPLC. If machine makes more than one part per signal, we can increase the count by the number of parts machine makes for each signal. The production count is sent to the EZMarquee. EZTouch displays the counts and also periodically logs the count in the USB or Micro SD card (the demo program logs it every 2 sec; in practice users may record it every hour or every day). When the EZPLC receives a machine down signal, the panel would prompt user to enter a code for a reason for machine being down. The EZPLC would track the downtime of the machine, and display this on the panel. The Panel would show an alarm as long as the machine is down. The alarm is also set to send an email and logs the downtime as well.