The spindle is at the heart of a machine tool and so plays a decisive role in the dimensional accuracy and surface quality of the respective workpiece.

High speeds and the heat generated result in the axial extension of the workpiece spindle and to the resultant positioning error during finishing of the workpiece.

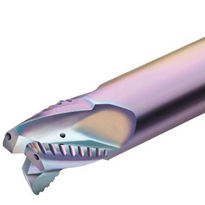

The new miniature eddyNCDT SGS 4701 sensor measures the thermal and centrifugal force extension of high-frequency spindles by measuring on the labyrinth-ring. The measured values are fed into the CNC machine tool as correction values and compensate for any positioning errors.

The miniature eddy current sensors have dimensions of 4.5 x 10 x 12 mm³ or 4 x 4 x 10 mm³ and can be integrated with the controller into the machine tool spindle.

For ease of handling and in order to achieve maximum accuracy, the eddyNCDT SGS 4701 is factory calibrated for ferromagnetic and non-ferromagnetic materials used by the customer.

The temperature of the eddyNCDT SGS 4701 sensor is measured via the resistance of the eddy current coil for temperature compensation. This signal is also available to the customer, which can eliminate the need for any additional temperature sensing technology.

This sensor is now available in Australia and New Zealand via Bestech Australia as a standard product and suitable for any OEM modifications.