Improvements can also be realised, at a Significantly lower up frontcost,through the measurement and automation of smaller processes such as:

- Monitoring iron ore wagon loads and automating the opening and closing of the hopper during loading.

- Monitoring load, speed and driver behaviour on haul trucks and providing real -time feedback to drivers and management to reduce tyre maintenance/replacement costs

- Automatically turning off dewatering pumps when pre-set temperatures are exceeded

- Automatically turning irrigation or dust suppression systems on and off based on onsite weather conditions (e.g wind speed and direction/rainfall)

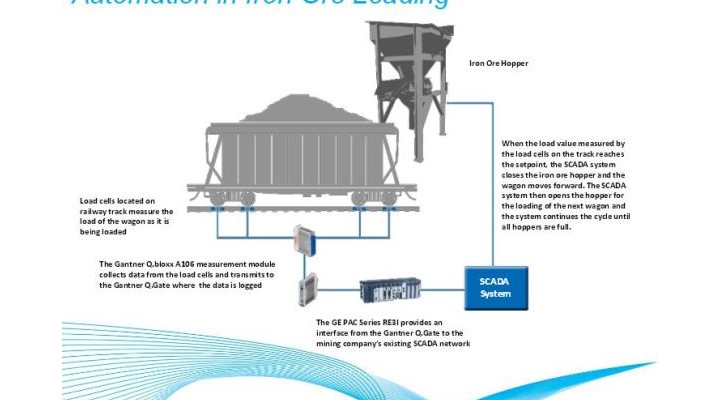

An exmaple of project of Automation in iron ore loading

Customer: Iron ore producer in Western Australia

Application: A system that integrates with the existing SCADA system to automate the opening and closing of the iron ore hopper based on the load of an individual wagon as it is being loaded.

Benefits:

- Optimisation of wagon capacity

- Increased accuracy of load for billing purposes

- Minimising overloading errors

- Minimisation of human intervention during loading provides continuation of throughput

Equipment:

- Gantner Q.gate DP Test Controller

- Gantner Q.bloxx A106 Measurement Modules

- GE PAC Series RX3I

Since 1984, Pacific Data Systems has been providing the tools to help our customers gather the critical information needed to make faster and smarter choices.

For more information on how we can help you please call or use the enquiry box for a direct reply.

-205x205.jpg)