Sustainability has become one of the main drivers in the world of infrastructure, construction and management. As Australia strives towards meeting emission targets and creating more environmentally sustainable infrastructure networks, minimising wear and tear on vehicles as well as reducing running costs has become an important factor in fleet operating systems.

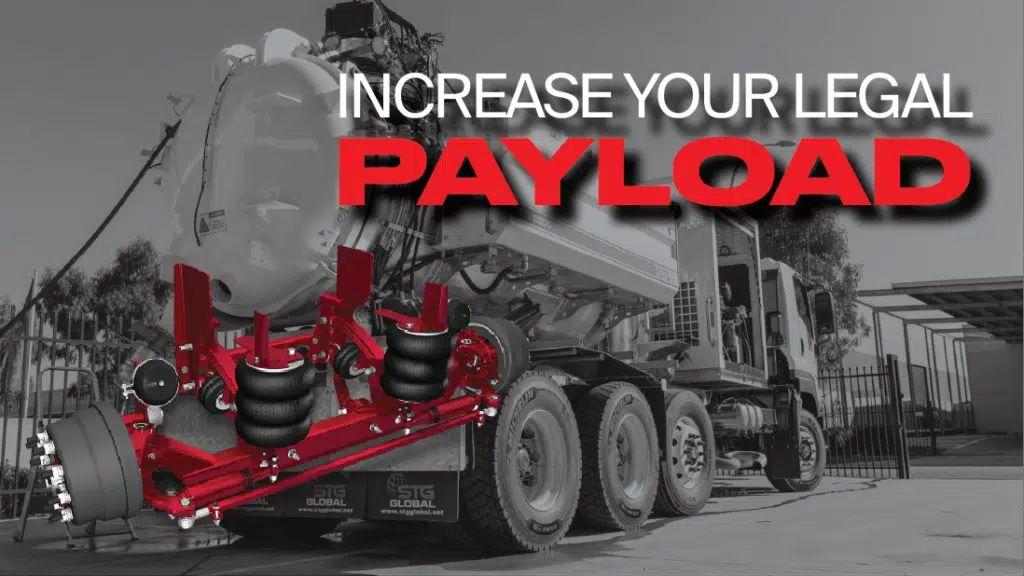

STG Global has recently introduced a steerable lift axle to its product line, with the steerable axle lift being able to lift or lower one or more sets of wheels from the road surfaces. The lift axles have a series of significant advantages, including increased fuel efficiency, minimising wear and tear, and improved sustainability management. With the added ability to steer the lift axles, you can further reduce the wear on tyres and the strain on static fittings caused by cornering in tight situations.

In this article we are going to lift the lid (pun intended) on steerable lift axles and the advantages they can bring to your fleet management strategy.

It’s an Up and Down World!

It would be fair to say that the global economy is in turmoil at present. With supply chains disrupted by shipping bottlenecks and various conflicts, the ongoing effects of the COVID-19 pandemic, and general instability on the geopolitical stage, keeping our infrastructure systems operating on something like an even keel has become increasingly difficult.

Factoring sustainability into the mix adds another level of complexity to your company’s operations. So making sure that your fleet can meet both your own sustainability targets, and those of the government, is an important consideration when choosing new equipment.

The rising cost of debt

With uncertainty still a major problem among financial institutions, interest rates continue to fluctuate wildly. With this in mind, being able to make your vehicles more reliable, and less costly to operate, can ensure that your fiscal costs can be minimised.

All the small things

When it comes to saving resources – and consequently saving money – it’s the small things that count. Being able to minimise wear and tear on your gear, using less fuel, and keeping your fleet numbers to a minimum: all these small factors can add up to big savings.

And fitting a steerable lift axle to your trucks is a great way to bring about these small savings.

Picking it Up and Putting it Down

The new STG Global steerable truck lift axles can give your rigs up to 35% greater legal maximum payload. And whatever your company’s business is – be it mining, infrastructure construction and management, or distribution – that’s a sizeable addition to your payloads.

Steerable lift axles mean that your fleet can be smaller because you’ll have to make fewer trips to deliver the same payloads, be able to stay on site longer and reduce the costs of fuel, maintenance and tyres.

Lightweight and manoeuvrable

STG Global’s passive steer axles and suspension systems are up to 315 kilograms lighter than conventional lift axles. Fixed “lazy” axles generally offer less manoeuvrability than steerable systems. They also increase the strain placed on components during a turn which can result in breakages and downtime. Steerable lift axles reduce the scrub load on tyres during turning, which leads to increased tyre life cycles and fewer wear-induced punctures.

Feature-laden to maximise lifespan…and minimise costs

The new steerable lift axles that STG Global now offers to our customers have a range of features designed to provide maximum lifespan, efficiency and durability including:

Zero-torsion rubber bushes: Worn bushes are one of the most common reasons for fleet downtime. By eliminating radial and axial movement, the bushes fitted to STG Global’s steerable lift axles substantially cut down wear.

Bolt-on axle seats: By utilising bolt-on seats, the axles can be easily adjusted to allow for different tyre sizes or ride height changes. This will ensure alterations to the system are less costly, as you simply change the seats according to your needs instead of changing the entire axle.

Secondary bump stops: Australia’s road infrastructure includes a lot of rough tracks into back-of-beyond places. So when you’re outback trucking, the lift axles fitted to STG Global’s range incorporate a secondary mechanical bump stop mechanism to transfer excess load to the axle seat.

Weld-free hangers: Welds can come apart under the stresses created by long distances and harsh road conditions. Our lift axles have a flat hanger design that removes several weld seams and allow flexibility in fitting to any configuration of chassis.

Sustainable and Future-proofed.

Being able to minimise running costs, own fewer vehicles and make those vehicles last longer is key to ensuring that your company meets – and even exceeds – your sustainability goals. Furthermore, putting less stress on infrastructure networks such as roads is a vital consideration when it comes to choosing the correct chassis configurations for your fleet.

At STG Global, we are dedicated to providing the most up-to-date truck chassis technology to incorporate into our industry-leading waste management, mining and infrastructure maintenance machinery. Our new steerable lift axles are just a part of our ongoing quest to provide the most durable, efficient and sustainable truck body systems available in Australia.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)