Based on the outskirts of Sydney, Le Mac is no suburban start-up. In fact the award winning company has built a reputation for innovation and progressiveness that has probably been unrivalled in the domestic industry for more than a quarter of a century.

Le Mac first opened for business, in 1984 when Mike and Lynda Cowan began importing shrink sleeves from Fuji Seal in Japan, where they had lived for seven years, first as students, then working there. Their move into shrink sleeves at a time when no-one else in Australia was doing it received a timely boost from the Tylenol tampering incident in the US in 1982. This multiple homicide in which 7 people were poisoned by cyanide-laced capsules led to all pharmaceutical companies requiring tamper-evident packaging for their products.

Shrink sleeve of course was perfect for the job. At the same time the soft drink manufacturers were looking for ways to enhance their product, which provided a significant market for the fledgling Le Mac.

As the business grew so did their realisation that they needed to print their own sleeves, however this was a far from easy process. All sleeves in Japan were printed gravure, but Cowan knew that the high set-up costs and run lengths for gravure wouldn't be cost-effective in Australia. A chance meeting with South African Ken Fletcher at the 1996 Interpack provided the gateway to the company's entry into flexo-graphic printing. Fletcher had begun printing shrink sleeves by flexo in Durban, and was by co-incidence thinking of a move to the more stable environment of Australia.

Cowan says, "The two countries are similar in market size, number of SKUs and the like, so his early work was perfectly suited to the Australian market." Fletcher did indeed emigrate, and along with fourth Le Mac partner Paul McKimmie, took a stake in the growing company. Fletcher then began to design an enhanced UV flexo press that could print UV shrink sleeves.

Cowan says, "By 1998 we were up and running with our own flexo UV shrink sleeve press, and no one else had one at the time, anywhere in the world." Working in conjunction with ink suppliers and press manufacturers, the company made its breakthrough. There were many things to consider, the inks for instance had to have an elasticity, to go with the film as it shrank around the container. They had to be odour free, as some of the product was inside thin walled bottles and the print is on the inside of the film, meaning the ink is only one thin barrier away from the food / drink in the bottle.

Cowan says, "I took the results of Ken's work to Fuji Seal in Japan, and they were astounded, so much so that they sent a print team down here to study the process."

Clearly Le Mac was on the leading edge of technology at the time, driven by a growing market and a determination to provide a solution. Cowan says, "As soon as we began printing, the market went through the roof, and has remained strong ever since. We haven't noticed the recession, and work 24 hours a day five days a week as standard." In fact such was the success that the company won a major Commerce & Industries Award for import replacement. Clients come from the top drawer of the packaging world including names such as Unilever, Selleys, all the pharmaceutical companies, and Coca Cola, and the market is still growing.

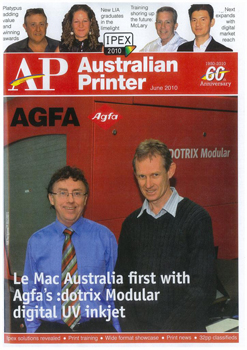

Now after more than a quarter of a century in business Le Mac has decided once again to invest in more innovation, this time in the form of Agfa's radical :dotrix high speed full colour digital inkjet printer. It will be the first in Australia and only one of a few outside Europe. Cowan says, "The packaging market is changing and Le Mac needs to change with it, and we need to continue to innovate, we need to offer a point of difference, and we need to move forward.

We need to offer our clients added value, offer solutions that will help their businesses grow. The market is moving to far more SKUs, more direct targeting – by demographic, by region, by promotion. The market needs short run variable data printing, and we will now be in the premier position to provide that.

"The global financial crisis has forced a lot of businesses to look carefully at their modus operandi. Long run lengths are on the decline, short and snappy are on the rise, so the marketers can keep the products moving swiftly off the shelves. Large stock levels are becoming a thing of the past, as retail environments work with more efficient logistics. The digitalisation of graphic design and prepress is helping facilitate this move to short run, especially when linked with a printer such as :dotrix."

The :dotrix is essentially a short run digital printer producing high quality colour print, with an ability to provide variable data printing, and on a wide web, relatively speaking, it is the widest digital printer available.

Cowan says, "Ken and I have spent a great deal of time following the digital print solutions coming onto the market. We have been following developments for ten years, talking and waiting until both the technology and the market were in a position that would enable us to provide a solution to our clients.

"We were particularly looking at two aspects, speed and web width, and the :dotrix addresses both of these. Shrink sleeves have to be printed on a wide web, as it is one piece of media that wraps around the entire container. We also required a high speed, and :dotrix has now answered this emphatically, running at up to 32 metres a minute. Digital printing of course means no makeready, which chops time dramatically, but the press still has to produce at a decent rate even for short runs."

The web width on a :dotrix is in fact even wider than Le Mac's regular flexo press at 650mm compared with 570mm. Cowan says, "there are multiple factors to consider with shrink sleeve, and we have modified the :dotrix accordingly. We have also worked closely with ink manufacturers, and will be running a UV ink specially formulated with low migration, and with low odour, well within European food and ink packaging guidelines."

As an innovator which has self developed many of its own solutions Le Mac isn't daunted by taking the first :dotrix in this region, even though it is a significant distance from Agfa's European base. Cowan says, "Agfa is renowned for its service support, and actually I have been really pleased with its support already. It is a complex piece of equipment, especially with what we have done with it, but the commitment we have had from Agfa has been beyond our expectations.

"We are really excited about having the variable data and short run capability. We can say to our customers that they can have as many different variations as they want, and customers will rise to that. This technology will also open new, non-label market opportunities for Le Mac which will focus on customisation and on demand print."

Cowan's visits to Agfa's existing customers overseas and his own research lead him to believe that some 40 per cent of turnover will ultimately come from digital, motivation enough to get into the market.

Le Mac will promote its new solution under the 'no run is too short' USP, and Cowan believes that it will not only open up new markets for the company but will strengthen existing ones. Developments such as the new light fast ink from Agfa that promises two or three years of resistance to the rigours of the sun will be promoted heavily to the market by Le Mac, as will the whole on-demand print business. Like all digital printing solutions :dotrix can print at the drop of a hat, once the file has been delivered to Le Mac and ripped, it is simply a case of ensuring the correct media is ready and off you go.

Cowan says, "Many of the :dotrix users we have visited in Europe are entrepreneurs who believed that by installing and running :dotrix new markets would open up for them, and so it has proved. They are all developing new markets, and we believe Le Mac in Australia will be no different."

In fact, such is Le Mac's confidence in the growth of the market that the company is ordering a second :dotrix, due to come in around Christmas. Cowan says, "The world is changing, the world is moving fast, and Le Mac is intent on supplying that world."

Le Mac's commitment to developing the market and being in the vanguard of change into the future is seen in many aspects, for instance Le Mac sponsors one of the Southern Cross awards for student packaging design, not surprisingly in the shrink sleeve category. Cowan says, "Of course we want to promote innovative packaging and encourage young people to enter the industry."

Le Mac is also a major Industry Partner of the University of Western Sydney's Careers & Cooperative Education Programme. Le Mac itself is an award recipient – it has won numerous gold awards for print quality at the Afta (Australian Flexo Technical Association) Awards and in addition has twice won the PCA Best in Show award in the last five years, a remarkable achievement. Cowan says, "Our approach is holistic, for instance we don’t describe ourselves as a label printer, we are container decoration specialists."

In the Australian shrink sleeve industry Le Mac is the biggest player, in a field that has narrowed in recent years to just two main operators. Cowan says, "Shrink sleeve is a far from straightforward technology." Le Mac's recent innovation includes a new linerless self adhesive label. Cowan says, "One of the biggest targets of the PCA is for a reduction in packaging landfill. Until now the liner on self adhesive labels went into landfill, our new solution means no liner, so no landfill."

Clearly the line of innovation that has underpinned Le Mac's consistent growth – 2009-10 will be a record year – is continuing with the investment in the country's first :dotrix. Expect more awards to follow.