Rotacaster Wheel was recently approached by a customer who encountered problems when moving pallets that weighing up to 1,200 pounds. Employees moving the pallets would have a difficult time keeping the product moving in a straight line. Additionally, the force required to move product across the ball transfers was more than desired.

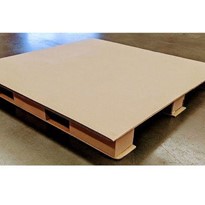

The transfer table measures 61” x 66” (155cm x 168cm).

The very simple yet effective solution was to use 630 48mm Rotacasters across 30 axles.

A lay-out of Rotacaster 48mm wheels was designed by Magnus Mobility using Rotacaster’s prefabricated aluminum mount channels to provide the lowest rolling resistance for the pallets along the packaging lines. The design provided the proper load support for the pallets’ 6” square pads. The expected improvements were achieved. The honeycomb pallets were easier to move across the Rotacaster transfer table, rotation ofpallets was easily accomplished manually and the directional control was improved greatly. Now loads of card and paper products arrive and are easily rotated and precisely positioned. The solution requires no power to the Rotacasters and minimal maintenance, while delivering reliable productivity.

For more information on how we can Improve the Movement Pallets on your Transfer Table please call or email us today.