Australia is a huge country. And its economy relies heavily on its ability to efficiently and effectively transport goods around the country – both short and long haul. Whether it’s imprinted manufactured goods or commodities for exports, our transport infrastructure and capital – trucks and trains – is essential to our economic productivity.

Whether transporting by truck or rail, a key factor to our national economic success and the profitable success of individual enterprises is the ability to use our transport infrastructure safely, optimally and profitably. Without those three things accounted for, our competitive advantage – as a nation and as individual companies – starts to fall away.

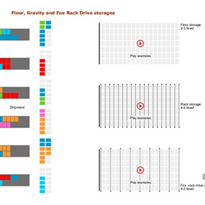

One of the key elements of optimising transport efficiency, maximising profitability and ensuring safety and compliance is the effective management of load configuration – both in terms of load spread and weight. By maximising payload, ensuring accurate and balanced load spread across axles and/or bogies and reducing overloads and poor load distribution, revenue is maximised and maintenance costs are drastically minimised. It’s a fine balance, for sure, but it’s a critical balance to get right because getting it wrong causes a multitude of problems.

In a recent report prepared for Infrastructure Australia, PWC identified payload and axle load management as a critical element in making rail freight transport economically feasible, particularly in relation to short hauls in and around major ports. https://investment.infrastructure.gov.au/files/reports_and_key_studies/Optimising_the_use_of_rail.pdf

The report noted that maximising tonne axle loads in order that they are fit for purpose to attract and retain freight volumes results in improved linehaul economics and reducing the potential distance at which short haul rail freight works.

In Australia’s highly regulated freight transport environment, succeeding in finding these kinds of efficiencies means that freight and logistics managers need to be able to accurately measure, record, analyse and communicate the most minute detail about freight loads right down to the individual bogie load carrying statistics. In high volume transport environments, where the road freight alternative might seem very appealing and easy, this can be a critical point of difference.

And the same advantages apply on longer haul regional freight routes, although the drivers are slightly different – particularly because, while the opportunities to improve tonne axle loadings on regional rail networks is naturally greater, the drivers for investment are lower due to the reduced much lower freight transport densities – so getting it right is critical to the investment thesis.

To maximise the freight opportunities from rail, operators need to measure, understand and manage their rail fleet from the driving infrastructure right through to each individual bogie’s balance and configuration.

There are a variety of weighing and balancing systems that are specific to managing rail haul vehicles but importantly it is essential to invest in a highly accurate, reliable and industry proven system that is purposely designed for the task.

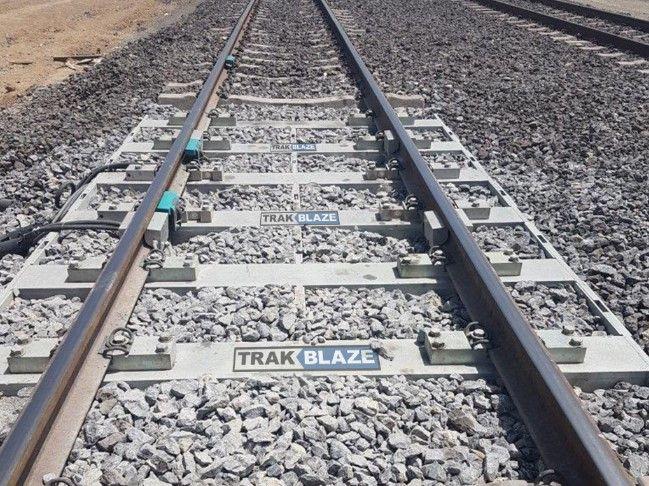

Trakblaze have one of the largest ranges of rail weighing and balancing products and is also synonymous with only manufacturing quality, reliable and highly accurate rail systems.

Getting the basics right benefits us all, from producer to consumer.