HMI is the interaction between a person and a machine. This can include control panels, with input devices including keypads and keyboards to control the machine. Poorly designed HMI can result in not only frustration for the user, but difficulty using the machine.

Companies like Reid Industrial Graphic Products develop HMI systems which streamline the interaction between machines and humans.

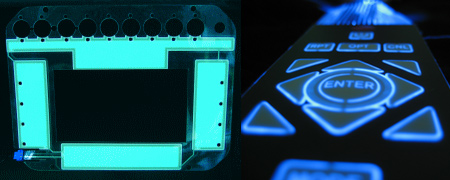

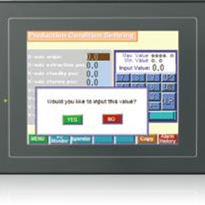

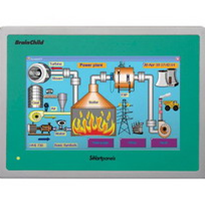

For example, products such as membrane keypads can be combined with backing panels and touchscreens can be combined with custom graphic overlays.

"What we do is the keypad side of things, or controller, and we work with customers to develop solutions for them to be able to control their machine based on our skills and the sort of products we can offer them," Trevor Johnson, sales manager at Reid Industrial Graphic Products told IndustrySearch.

Customers who use HMI commonly want to make machine processes more efficient. For example, they might have mechanical switches or they might have a PCB they want to make into their main keypad.

"They might have something from one of our competitors which have done something for them and it’s not been up to their standard. Or they might come to us for a bit of local support and a bit of R&D as well," Johnson said.

"Most of them come to us if they’ve got issues with their current supplier or if they’ve got new products."

HMI aims to streamline processes and make them more efficient. For example, Reid Industrial Graphic Products has worked with Total Aerospace Solutions, who fitout the Royal Flying Doctors planes.

The objective was to save on weight inside the plane and to have a different setup for controlling the arm on the stretcher bed and devices inside the plane.

"What they’ve now done is swapped virtually all of that over to memory keypads with backlighting, so it saves on weight," Johnson said.

"Functionality is much better now by being able to incorporate lighting into it."

HMI, however, is not a one-size-fits-all process – every solution at Reid Industrial Graphic Products is customised to the client’s needs and not one piece is the same.

Part of HMI can include prototypes, which typically comprises the first part of the process. This is usually digitally printed. This prototyping phase can include creating a limited number of products, usually less than 10, to see how the system works.

HMI solutions at Reid Industrial Graphic Products can usually be turned around in 15 working days.

"Sometimes the R&D artwork approval stage can take anywhere from a week to two weeks, but our standard is 15 working days from artwork approval," Johnson said.

"If it’s a repeat job – because we do get a lot of those – it’s still about 15 working days. That’s our basic turnaround time and that can vary sometimes."