In today’s electrical networks, deviations from ideal power quality conditions are often due to increasing non-linear and other loads disturbing the grid. Power generation is also becoming more complex with new players and technologies entering the business. The consequences of poor power quality can inflict serious losses for businesses. In the worst-case scenario, it may pose a threat to human life in mission critical applications and highly sensitive environments such as hospitals.

How does the Fluke 378 FC help monitor power quality issues?

As the first clamp meter with FieldSense technology, the Fluke 378 FC Clamp Meter democratizes power quality testing and changes the rules of the game by improving existing workflows and creating new ones. Industrial electricians and frontline technicians can now perform basic troubleshooting and/or maintenance rounds of single or 3-phase systems, discovering power quality problems that would not have been found otherwise. The Fluke 378 FC empowers front line technicians to make basic power quality measurements and rule out power quality issues in these three categories:

- PQ-Volts

- PQ-Amps

- PQ-PF (Power Factor)

PQ-Volts and PQ-Amps are based on Total Harmonic Distortion (THD) which is defined as the ratio of the sum of the powers of all harmonic components to the power of the fundamental frequency.

Power Factor (PF) is an expression of energy efficiency. It is usually expressed as a decimal value, with 1.0 being the most efficient—and the lower the value, the less efficient power usage is. Power factor is the ratio of working power, measured in kilowatts (kW), to apparent power, measured in kilovolt amperes (kVA).

The PQ Indicator is a background function which appears automatically when a power related issue is identified. The meter is continuously checking the THD% of voltage, current, and monitoring the power factor. If it exceeds a certain threshold, the enunciator shows a power quality problem.

Setup:

- Turn the control knob to

(Fieldsense)

(Fieldsense) - Connect the clamp to ground with the ground lead.

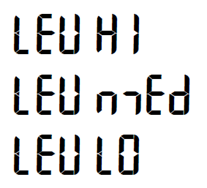

If the total harmonic distortion or the power factor is outside the optimal range for the sensitivity level, the related indicator shows on the display:

![]()

This indicator shows up on the Fluke Connect application as well.

Sensitivity levels

Sensitivity levels on the clamp meter are adjustable to High / Medium / Low levels, each with different thresholds for PQ – Amps, PQ – Volts, PQ – PF. High is the most sensitive setting, where small changes in THD will trigger the indicators. The default setting is high and individual thresholds are not customizable.

| Function | Sensitivity | ||

|---|---|---|---|

| High | Medium | Low | |

| PQ-Amps | 10% THD | 25% THD | 50% THD |

| PQ-Volts | 8% THD | 10% THD |

15% THD

|

| PQ-PF | 0.9 | 0.75 | 0.6 |

Steps to change the sensitivity level

- Turn off the clamp

- Push and hold

‘Hold’ button as you turn the control knob to ? . The Clamp goes into the option mode

‘Hold’ button as you turn the control knob to ? . The Clamp goes into the option mode - Push

to go through the options and select PQ Sensitivity

to go through the options and select PQ Sensitivity - Push

button to change a setting

button to change a setting

- Release

to exit the options mode.

to exit the options mode.

Note: Anytime you release the ‘Hold’ button, the clamp exits the option mode but retains any changes to the settings.

Using the power quality indicator

Harmonics are the byproducts of modern electronics. Harmonics are an unwanted source of high frequency AC voltages or currents supplied to the motor windings. Determining intermittent faults in assembly machinery which could be caused by harmonic fluctuations in power. Harmonic distortions could lead to fault conditions on critical equipment, creating downtime. The 378 FC Clamp Meter with FieldSense and PQ indicator will screen for power quality issues and helps technicians determine if a PQ analyzer or a PQ expert is required for further analysis.

The 378 FC clamp meter helps identify efficiency in motors and drives to determine motor or drive capacity. Motor overloads occur when a motor is under excessive load, either through excessive current draw, insufficient torque, and eventual overheating. Overloading causes 30% of motor failures, which leads to inefficiency and reduced capacity. The 378 FC can serve as the first line of defense to spot power quality issues before determining if further diagnosis and analysis is needed.