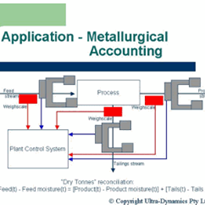

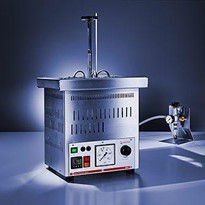

The 1735 Transmitter uses the measure of oxygen to calculate the level of water vapour by using the difference between the wet oxygen reading and the dry oxygen reading.

The Novatech zirconia probes incorporate the world’s most rugged zirconia sensors. Now there is a Novatech oxygen probe designed especially for baking and drying ovens.

Used with the 1735 Water Vapour Transmitter, the 1231HWV Oxygen Probe is capable of reading the oxygen concentration in atmospheres with up to 99.99% water vapour and at temperatures up to 600°C (1,100°F).

The 1735 / 1231HWV Water Vapour analysis provides rapid payback for processes such as:

• Drying ovens

• Baking ovens

• Paper drying hoods

• Gypsum and plasterboard dryers

• Timber drying kilns

The 1735 / 1231HWV water vapour analysis can provide accurate moisture control in atmospheres up to 600°C:

Easy to operate, reliable and no regular calibration needed. Select the unit of measure to display and output from:

• Water vapour %

• Dew point

• Mixing ratio

• Absolute humidity

• Specific humidity

• Dryer relative humidity

• Oxygen %

Accurate, rapid response, low drift, robust

zirconia oxygen sensor.

Highly responsive, eg: typically 3 seconds

for indirect heated applications.

• RS-232 / RS-485 ModbusTM interface

• Two isolated 4-20mA outputs

• Programmable alarms

Accurate and reliable

The oxygen sensor, which measures water vapour due to oxygen displacement in the oven atmosphere, provides accurate and

virtually drift-free measurement for years.

Controlling humidity

The 1735 / 1231HWV can be used with controllers, including PLCs, to provide accurate continuous control

of the moisture level.

Direct fired processes

The 1735 / 1231HWV measures the “wet” oxygen level of the process using an in situ zirconia oxygen probe and can accept a remote signal input (4-20mA) proportional to the dry oxygen level to then calculate the percent water vapour in the process. If this signal is not available from an existing CEMS installation then the 1735 can be supplied with a reference gas sensor (See separate brochure, model 1234) and a simple sampling system to determine the “dry” oxygen level in the process.

The 1231HWV Oxygen Probe and the 1735 Transmitter is designed in Australia and manufactured in the Melbourne factory.The sensor embodies the research and development of Australia’s premier research organisation, CSIRO.The probe can be inserted directly into the oven / dryer therefore eliminating the need for a high-maintenance sampling system.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)