What is it?

Additive injection is the process of accurately blending a base material (diesel) with two or more additives using controlled doses. This process is more commonly used in the creation and mixing of fuels, such as diesels, petrols and jet fuels. Each fuel manufacturer has their own additives to make their fuel burn better in the engine to increase performance.

How does it work?

When creating a unique fueling product by mixing the required materials a main or primary flow material is used as the base for the product. An additive is then dispensed, typically from an external source into a tank with the primary product. In some cases this is a colour because of excise or tax requirements.

The Innovec AIC System

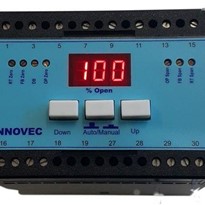

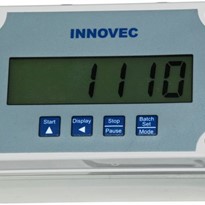

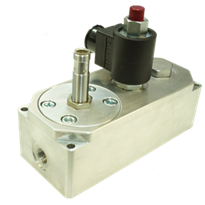

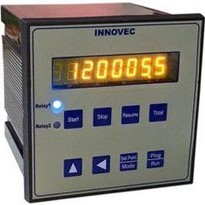

Innovec has multiple additive injection solutions, including an Additive Injection Controller (AIC) that is typically supplied in an explosion proof housing (rated for AICEX and ATEX) which can be configured by infra-red remote control or RS485 communication. When combined with an additive injection manifold the AIC, creates a complete additive injection solution for the user.

In 2022 Innovec is releasing a brand new 12 channel Additive Injection Controller with a 7” colour LCD touch screen. The new model will be available with all the great features of previous models and more, including a brand new microprocessor with advanced speeds and capabilities. This product will be shown at Stocexpo in Rotterdam, now on the 23rd May.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)