This new version of the machine has been completely redesigned to meet today's demanding worksite requirements. It features the latest Haulotte innovations and offers the safest working at height experience on the market. Its new design and smart engineering meet all the challenges of working-at-height up to 20 meters.

The HA20 RTJ: optimum productivity and safety

Versatile and easy to use, the HA20 RTJ is ideal for working on challenging outdoor terrain. Thanks to its articulated arm and its 11.9 m horizontal outreach, the HA20 RTJ overcomes obstacles and reaches the most inaccessible working areas. With this feature, the machine ensures maximum safety and productivity. Furthermore, the Haulotte Dual Reach option offers to increase load and tilt capacities.

On the job site, there are many situations where you need to carry a lot of weight in the basket while working on sloping ground. To meet these challenges and boost productivity, Haulotte introduces the Dual Reach now available on the new HA20 RTJ as a standard equipment.

Aware of the environmental challenges facing the construction industry, Haulotte has chosen to adapt the motorization of the new HA20 RTJ. Its new engine, rated at less than 18.5 kW, combined with optimized mechanical and hydraulic systems, delivers optimized torque while reducing fuel consumption by 35% to 50%**.

Haulotte engineers have also redesigned the machine's chassis and integrated an improved hydraulic architecture with axle drive. Thanks to these engineering improvements, the number of hydraulic hoses has been reduced by 35%***, access to components and maintenance operations are facilitated, and downtime is reduced.

Haulotte is committed to improving the environmental impact of its products. This concern is reflected not only in the conception and design of its products, but also in their use, thanks to numerous innovations and on-board technologies. The new HA20 RTJ PRO boasts a 97% recyclability rate.

Tools for fleet management and diagnostics

The HA20 RTJ PRO offers several on-board diagnostic solutions to facilitate fleet management and minimize downtime. These tools enable the collection of machine operating data, the resolution of fault code, and the rapid identification of troubleshooting:

The SHERPAL telematics solution, enables you to monitor the status of your machines remotely and in real time. It considerably reduces downtime by providing access to fault codes and actions to be taken. Telematics data are also very useful for organizing the routes of technical teams and preparing interventions.

On the job site, there are many situations where you need to carry a lot of weight in the basket while working on sloping ground. To meet these challenges and boost productivity, Haulotte introduces the Dual Reach now available on the new HA20 RTJ as a standard equipment.

The Haulotte Dual Reach increases the load in the basket from 250 kg to 350 kg, and enables working on sloping ground up to 6°. Once Dual Reach is activated on the upper control box, the machine continues to elevate and work smoothly, limiting the number of back-and-forth movements between the ground and the working area. The Haulotte Dual Reach ensures greater safety and productivity on sloping grounds. When the Dual Reach option is activated, the machine's working envelope is automatically adapted to ensure perfect stability.

Excellent performance in rough terrain conditions

Equipped with standard 4-wheel drive and 2-wheel steering*, the HA20 RTJ moves easily over all types of terrain. Its oscillating axle allows the machine to adapt to all conditions, keeping the wheels in constant contact with the ground.

The automatic differential lock provides extra traction on uneven or sloppy ground, allowing the operator to maintain full manoeuvrability and navigate obstacles without difficulty. The HA20 RTJ retains its excellent rough terrain capabilities thanks to the combination of a new engine and a new hydraulic architecture (axle drive).

Even more safety

Taking care of people is part of the Haulotte Group's DNA and its top priority, the HA20 RTJ is equipped with all Haulotte safety features in addition to the Haulotte Dual Reach innovation. Thanks to its proportional controls, the HA20 RTJ offers precise, jerk-free driving and guarantees a smooth approach to the working area. The ergonomic control panel ensures unrivalled operator comfort.

The HA20 RTJ features the Haulotte Activ'Lighting System: ten LED spotlights enable the operator to load and unload the machine in complete safety in low-light conditions. The two new reflective stickers judiciously placed on the counterweight give the machine excellent visibility in urban environments or when co-activity is required. The Haulotte Activ'Shield Bar equipped the HA20 RTJ PRO model as standard. In a entrapment situation, the operator is pushed against the bar, and the machine stops automatically. The wide clearance protects the operator from being crushed.

Reduced carbon footprint and easier maintenance

Aware of the environmental challenges facing the construction industry, Haulotte has chosen to adapt the motorization of the new HA20 RTJ. Its new engine, rated at less than 18.5 kW, combined with optimized mechanical and hydraulic systems, delivers optimized torque while reducing fuel consumption by 35% to 50%**.

Haulotte engineers have also redesigned the machine's chassis and integrated an improved hydraulic architecture with axle drive. Thanks to these engineering improvements, the number of hydraulic hoses has been reduced by 35%***, access to components and maintenance operations are facilitated, and downtime is reduced.

Haulotte is committed to improving the environmental impact of its products. This concern is reflected not only in the conception and design of its products, but also in their use, thanks to numerous innovations and on-board technologies. The new HA20 RTJ PRO boasts a 97% recyclability rate.

Tools for fleet management and diagnostics

The HA20 RTJ PRO offers several on-board diagnostic solutions to facilitate fleet management and minimize downtime. These tools enable the collection of machine operating data, the resolution of fault code, and the rapid identification of troubleshooting:

The SHERPAL telematics solution, enables you to monitor the status of your machines remotely and in real time. It considerably reduces downtime by providing access to fault codes and actions to be taken. Telematics data are also very useful for organizing the routes of technical teams and preparing interventions.

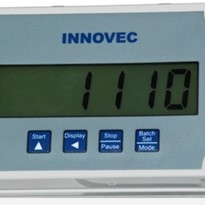

The Haulotte Activ'Screen on-board diagnostics tool gives access to machine parameters and provides key information on machine status in real time.

These functions are also available via the Haulotte Diag mobile application, which also offers advanced diagnostics with detailed resolution procedures.