The Swift-Cut Plasma system uses the very latest Technology such as Digital Torch Height Control (DTHC) and Dynamic Cut Control (DCC). DCC is standard on all Swift-cut machines powered by a Hypertherm powermax 65/85/105/125 systems.

In basic terms DCC is control of cutting amps and air pressure automatically on your Hypertherm unit without having to set it manually.

By automatically controlling these settings cut quality is improved as it can be adjusted dynamically to suit individual features in the program.

Our team will be demonstrating the machines and the Swift-Cam automated cutting software during the expo, showing how the Swift-cut with its many features will allow you to take control of your metal cutting requirements.

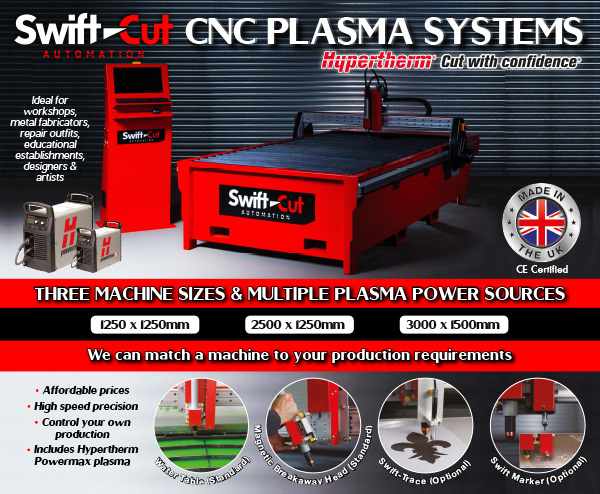

Water Table: Water tables are a much more effective system for collecting the sparks, dust and smoke emissions inherent to the plasma cutter, it has the added advantage of cooling the plate as it cuts.

Magnetic Breakaway Head: The magnetic breakaway head will quickly shut down your Swift-Cut machine in the unlikely event of your torch crashing, eliminating damage to the torch and improving safety.

Swift-Trace – Optical Reverse Engineering (Optional): Need to reverse engineer a part from a sample or hand drawn sketch? See how the optional Swift-Trace camera can go from a line drawing to cutting your design in four simple steps.

Swift Marker - Plate Marking (Optional): On the day see how the optional Swift-Marker unit can be used to

automatically mark text, fold lines and centre marks on components prior to profiling to avoid costly second operations, great for part numbering or serial numbering of parts.