Recently Igor has begun to supply his services on an international market with sales into New Zealand Thailand and the Philippines.

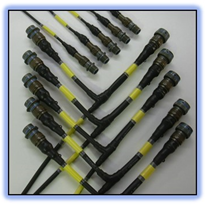

Now Igor has cracked a new market, completing a design and manufacture package for Linde-Korea for 500 customised fittings - a complete package of socket weld fittings for oxygen service that was delivered for construction of a new Linde-Korea filling plant.

During this project we worked tirelessly with the client to deliver design and manufacturing to an incredibly tight timeframe. It took us two weeks to design all the components and six weeks to complete the manufacture of the items ready for dispatch.

Our association with the project was made through TIG in Thailand, who sent an enquiry through our web site (www.hifraser.com) for the manufacture of specialised oxygen fittings for this large new filling plant.

However it soon became clear that the technical specification of the RFQ package required further definition and so TIG passed us directly through to the engineers at the plant. Our final drawings were the culmination of gaining a detailed insight into the customer's requirements and working to manufacture components that integrated seamlessly into the Oxygen filling system.

In addition to the socket weld fittings contract our work scope expanded including single swivel connectors custom manufactured from Oxygen approved materials. We are also working with Linde-Korea to develop an ongoing association via a continuous maintenance program at their new plant.

Our MFG section also designs and manufactures our own range of HIFCO products in-house including needle valves, oxygen filters, swivel joints, flexible hoses, face seal (zero clearance) couplings, gas filling connectors and flanges.

We have the capability to machine and fabricate items to customer design as well as provide engineering support where required by our customers.

MFG specialises in turning, milling and drilling of a wide range of exotic materials including, SMO254 (super austenitic stainless), copper-nickel alloys (CuNi90/10 and CuNi70/30 to BS2874), monel alloys (M400 and K500), nickel aluminium bronze (NAB to NES 833), phosphor bronze (PB 102), gun metal (GM to BS 1400), brass alloy (BR-686 to AS 1567), stainless SAF 2205, SAF 2207 etc. All items are provided with full traceability.