The Global Water Engineering (GWE) RAPTOR™ (Rapid Transformation of Organic Residues) anaerobic digestion technology – represented in Australasia by CST Wastewater Solutions – extracts biogas from virtually any biological waste stream, including municipal food wastes from restaurants, food service facilities, grocery stores, and municipal solid waste, as well as organic wastes from industrial processing facilities, food and beverage plants and agribusinesses. The technology has been proven in Australia, in applications such as Oakey Beef Exports in Queensland.

"It's fantastic to get recognition for this technology, which turns a costly and odorous problem into a source of renewable energy in the form of biogas," says Managing Director of CST Wastewater Solutions, Michael Bambridge.

"Typically the costs involved in implementing the technology are repaid within the first five years – sometimes sooner – and then it can go on delivering benefits and profits virtually in perpetuity," he said.

The RAPTOR™ concept

The environmentally advanced technologies transform waste organic materials and wastewaters from an environmental liability into a profit centre.

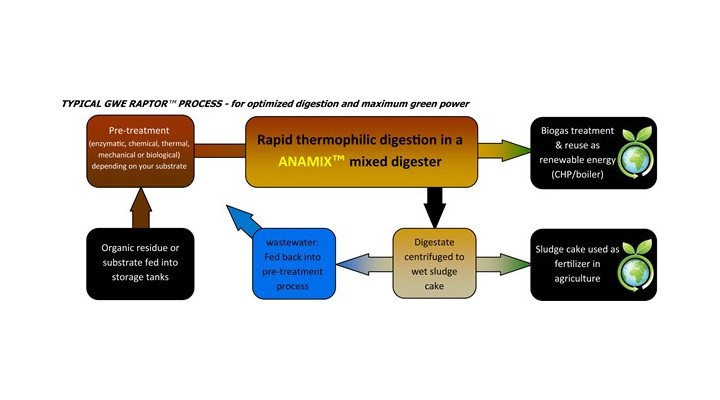

One of the technologies, GWE's RAPTOR™, is a powerful liquid-state anaerobic digestion process that consists of enhanced pre-treatment followed by multi-step biological fermentation.

RAPTOR™ is ideally suited to both industrial and municipal applications in Australasia, with its most recent global installations, such as Del Monte Philippines, demonstrating its potential for similar applications here.

How it Works

Intake Logistics and Slurrying

Suitable substrates can be liquid slurries or wet solid residues. A RAPTOR™ plant always starts with liquid storage tanks or solid substrate storage boxes, tanks, bunkers or silos. Solid substrate is more or less continuously extracted from the reception and storage boxes into the Slurring Stage. A slurry is prepared in a quick mixer device, consisting of a hopper with a rugged double shaft disk shredder, liquid inlet pipe and a slurry extraction pump. Liquid (liquid waste or recycle effluent liquids) is automatically added in a suitable amount to convert the solids substrate into a liquid slurry. When treating different wastes, the art of blending the substrates is key to successful operation of a RAPTOR™ plant.

Examples of RAPTOR™ substrates include:

- Food waste

- Market surplus

- Kitchen waste

- Off spec fruit and vegetables

- Excess harvest

- Agro-industry residues

- Beet pulp

- Tapioca pulp

- Restaurant waste

- Vegetable/potato waste

- Industrial residues

- Brewery waste (spent grain)

- Food processing waste

- Paper mill sludge

- Energy crops

- Corn (silage)

- Various grasses

- Algae

The Right Pre-treatment for Optimised Rapid Digestion

Diverse substrates require a range of different pre-treatments to improve the performance of the rapid digestion process to deliver the highest possible conversion efficiency. GWE's RAPTOR™ plants can consist of one or more of the following pre-treatments:

- Enzymatic pre-treatment – In a high temperature enzyme reactor, for pre-treatment of certain (hemi-) cellulosic substrates, to solubilise organic matter prior to fermentation, enhancing fermentation speed.

- Chemical pre-treatment – By mild caustic treatment, at elevated temperature, for partial hydrolysis of hard to digest polysaccharides and proteins and to increase biogas yields.

- Thermal pre-treatment – Heating slurry for hygienisation (animal products), protein denaturation and cell autolysis, used in combination with enzymatic, chemical or mechanical pre-treatmen

- Biological pre-treatment – GWE's Thermophilic Acidification Reactor (TAR) enhances the digestibility of many organic substrates via partial solubilisation of solids, low pH induced protein denaturation and polysaccharide hydrolysi

- Mechanical pre-treatment – GWE's Powerpulper™ system to turn coarse slurry into a fine m It consists of a compact tank with a powerful cutter pump mixing system.

Rapid Anaerobic Digestion

The suitably pre-treated and blended substrate slurry is transferred into a mixed digester. As solids digestion occurs two times faster at high temperature than low temperature, thermophilic digestion (50–55°C) is usually preferred. High nitrogen substrates however require mesophilic digestion at 35-40°C, or at an intermediate temperature.

GWE's standard Anamix™ digester system uses highly energy efficient and low maintenance mechanical mixing with a large top entry mixer, and is available in sizes up to 3.2 mg (12,000 m3). Depending on the application, optional extras include a foam breaker fan, a scum buster system or a (sloped) bottom grit trap. Different reactor configurations can also be used.

Tanks are always fully insulated and heated externally, by recycling the digester content through a special heat exchanger. Depending on the substrate, loading rates of up to 10–15 kg COD/ m3 per day and high biogas production rates per unit reactor volume can be obtained in RAPTOR™ plants.

The Anamix™ reactor digestate is usually treated in a centrifuge for removal and disposal of the non-digestible solids (wet sludge cake), which are ideal as fertiliser in agriculture. Sludge cake drying and pelletising systems are also available on request.

The liquid concentrate constitutes a small wastewater stream, recycled to add to the fresh solid waste in the slurry-making stage, or recycled to a TAR pre-treatment, disposed of in a conventional anaerobic/aerobic or aerobic wastewater treatment plant, or treated in a dedicated wastewater treatment plant (RO-concentration/ evaporator). For agricultural RAPTOR™ plants, the digestate is usually stored, and spread out on the fields in the appropriate season as fluid fertiliser.

Biogas Use – Green Power from the RAPTOR™ Process

The biogas generated in the RAPTOR™ process is desulphurised and partially dried, using GWE's Sulfurix™ and Gasodrix™ systems, and consequently used in a CHP unit (Combined Heat and Power) for green power generation. Government aid under the form of grants, soft loans or regulated minimum prices for green power sold to the public grid often make green power generation an economically attractive application for biogas. Alternatively, it can be used in a steam boiler for steam production, in which case desulphurisation and drying is typically not need.