Flexible temperature sensors are the new frontier in accurate temperature measurements and easy maintenance. The WORM's mission: to fit nearly everywhere, to be quickly cut to the correct length, and to reduce the number of spare parts a plant has to keep on hand.

The WORM® is a flexible sensor for thermowell temperature assemblies. It was designed to replace restrictive, rigid, straight sensor probes with a universal strategy that saves time and money. When it comes to flexible and rigid temperature sensors, both can be inserted into thermowells or protection tubes, welded into place on boiler tubes or other objects, or clamped down for surface measurements. Both types of sensors are rugged, durable, and can measure a wide range of temperatures in industrial applications. So, why replace rigid, straight sensors?

Why Replace Rigid Sensors?

Rigid sensors have always posed installation and maintenance problems. It is difficult to work with rigid sensors - keeping the correct spares and replacing the sensors in "sagging" or dirty thermowells are some of the problems. When used with thermowells, a rigid sensor has to be the correct length to fit. That means a plant must keep several different lengths of spares in stock to fit every thermowell. If a thermowell sags from extreme heat or fills with debris, a replacement sensor often will not fit, and the thermowell needs to be replaced.

Replacing a rigid sensor can be difficult. Typically, a maintenance technician has to remove the enclosure cap, disconnect the wires from the transmitter or terminal block, disassemble the union, conduit and fittings attached to the transmitter and thermowell, and then move them out of the way before he or she can pull the rigid sensor out of the thermowell.

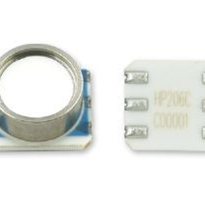

The flexible sensor was developed to ease these problems. The flexible sensor typically consists of a one inch, stainless steel sheath with an element and lead wires that are protected either with Teflon or fiberglass insulation. A flexible temperature sensor, such as the WORM®, slides into a thermowell or protection tube and is held in place with a spring (Figure 1).

Advantages include easy replacement during maintenance and minimal need for spares - flexible sensor wires can be trimmed to the correct length, simplifying the need for spare parts because "one sensor size fits all."