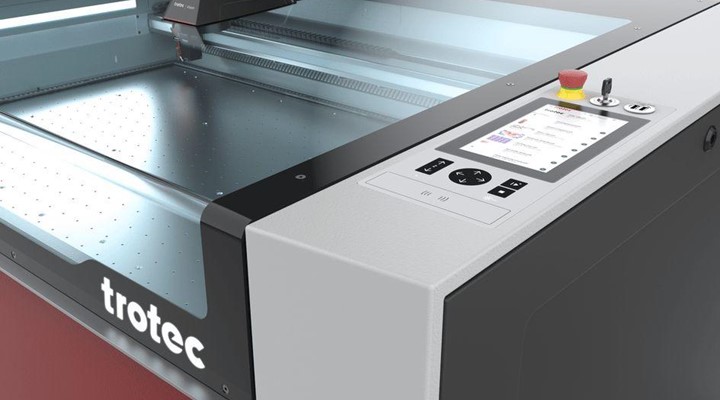

From a flash of inspiration about how to produce better stamps, a company was born that has made its mark on the laser industry. Trotec Laser was founded 25 years ago, and has made a global name for itself thanks to its high-quality service, innovative power and optimism. Christopher Müller, son of Trotec founder and today a member of the Trotec board of owners, and Andreas Penz, a general managing executive at Trotec Laser since 1996, share their insights into the past and the future.

From prototypes to over 800 employees worldwide and a turnover of 150 million in 25 years.

Trotec Laser was founded by Klaus Müller (Christopher Müller’s father) exactly 25 years ago. Müller was the CEO of Trodat, a traditional stamp manufacturing company from 1983 to 2002. His initial goal was to simplify and accelerate stamp production at his company.

“My father first learned about laser technology in 1991 in the USA, and quickly realized its potential: Producing text plates with a laser machine is much faster, simpler and more environmentally-friendly,” says Christopher Müller about the development.

Now the global leader in laser machines for engraving, cutting and marking, Trotec Laser has a workforce of more than 800 and generates sales of over EUR 150 million. It is anticipated that sales will pass the EUR 200 million mark by 2025.

Setting new standards from the very beginning

The first Trotec laser prototype was an adapted laser machine produced by another manufacturer. The prototype did not meet the desired quality standard. It was at this point that Andreas Penz, then a university assistant doing research in laser technology at Vienna University of Technology (TU Wien), came on board. “It was a modest start," remembers Penz. "Our research lab was set up in a container, where we fiddled about with early laser systems."

In 1996 under Penz' leadership, an in-house Trotec laser machine was developed and built. “The first machine set new standards in precision, dust protection and filter technology,” recalls Penz.

Keys to rapid development

“Many of the small stamp manufacturers not only produce stamps, but signs as well,” Penz explains. And many also want to use laser machines for this application. “As a result, we began specializing in other applications and discovered new, bigger markets that see stronger growth.” In 1997, Klaus Müller separated the laser machine division from Trodat and founded an independent sister company.

“Trotec Laser’s route to success would have been much more difficult if we’d kept the new division as a department of the old company,” says Penz, looking back. "The sales offices drive forward international expansion, and also promote quality standards by ensuring that local technical support is available.

“There are certainly cheaper laser machines you can purchase, but customers know that if they've got a Trotec laser, it’s going to work," explains Christopher Müller. "If a problem does arise, we are able to send a technician who speaks the customer’s language to the site very quickly, thanks to our local offices,” He adds.

Where is the journey heading?

In 2020, Trotec brought its own laser software, Ruby®, onto the market. In keeping with the age of digitalization, Trotec once again sets a new benchmark, evolving from being a purely mechanical engineering manufacturer to a software business. In the future, they don’t just want to stand out from the rest with their machines: Penz is convinced that, “Software is the real differentiating factor.” Priority is given to customer needs, including requirements for increased digital workflows, thus setting new standards for the customers’ success.