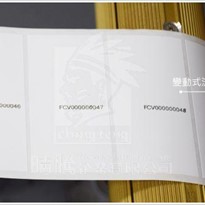

Opening for operation in 2006, EXELPrint is a Melbourne based niche label printer specialising in the printing of safety, testing, asset and identification tags. Working mostly in the electrical testing and tagging space, EXELPrint has established itself as an expert in variable data printing, with 90% of their business requiring variable data printing with everything from numbers, asset data barcodes, locations or product information.

TAKING THE NEXT STEP WITH SCREEN L350

As the business continued to grow, EXELPrint was looking for innovative ways to improve their products and service. To support its growth, EXELPrint invested in a new production line for its growing labels and tags print operation, which included calling on Jet Technologies to install a new Screen Truepress Jet L350UV digital label press. “We wanted to stay ahead of the market with current printing quality and customer expectations, so we knew we needed to step it up with better print services,” said Jason Kiekebosch, Managing Director, EXELPrint. When looking to improve their printing solution, EXELPrint needed a printer that integrated with current processes and had high-end processing computation for variable data. The new press will complement EXELPrint’s current narrow web print capabilities, to expand the potential offering that EXELPrint now needs to meet the demands of their customers. After extensive research and testing, particularly at Jet Technologies’ Sydney demonstration suite, EXELPrint found the Screen L350 to be their best option going forward.

IMPROVED CAPACITY AND PRODUCTION VOLUME

The Screen L350 has allowed EXELPrint to have the computation power for variable data printing, while keeping set-up times low.

Jason explained: “The addition of the Screen L350 from Jet Technologies enables us to go to the next level of tag and label production as we implement our 2020 vision strategy. ”The new label press allows EXELPrint to bundle jobs together to reduce materials and wastage. The materials and substrates are a large cost for our customers because they are rugged and are built to last the test of time out in extreme environments, so the reduction in wastage is important so we can pass these savings on to our customers.

DURABILITY

Being able to provide customers with more options was becoming crucial, and so EXELPrint needed a new solution that would provide them with more colour options, the ability to print on wider and different stocks, and importantly white ink. “Being able to customise our tags and labels the way our customers want them is an important part of our business,” said

Jason. “We tackle the difficult requirements for industrial labelling that others don’t. The L350 allows for great customisation.”

IMPROVED CAPACITY AND PRODUCTION VOLUME

The Screen L350 has allowed EXELPrint to have the computation power for variable data printing, while keeping set-up times low. Jason explained: “The addition of the Screen L350 from Jet Technologies enables us to go to the next level of tag and label production as we implement our 2020 vision strategy.” The new label press allows EXELPrint to bundle jobs together to reduce materials and wastage. The materials and substrates are a large cost for our customers because they are rugged and are built to last the test of time out in extreme environments, so the reduction in wastage is important so we can pass these savings on to our customers.

BUILDING STRONG PARTNERSHIPS WITH JET TECHNOLOGIES

This is the third Screen L350 Jet Technologies has sold in Victoria within the last year. “So far our clients have seen positive results in terms of improvement of efficiency and quality of their products,” said Jack Malki, Director, Jet Technologies. “The partnership with Jet Technologies and Screen Australia has been terrific, both in terms of their technical support and responsiveness. We look forward to partnering with them further as we develop more innovations for our customers,” added Jason.

FUTURE PRODUCT DEVELOPMENTS

EXELPrint has also ordered an additional finishing line, made by Rotary Engineering in Australia, offering unwind, varnishing, flexo, laminating, cold foil, semi-rotary, die-cutting, slitting and rewinding. “We have exciting product developments in the pipeline,” said Jason. “We pride ourselves on being an innovative business that utilises new technology, and we look forward to talking to our customers about those opportunities.”