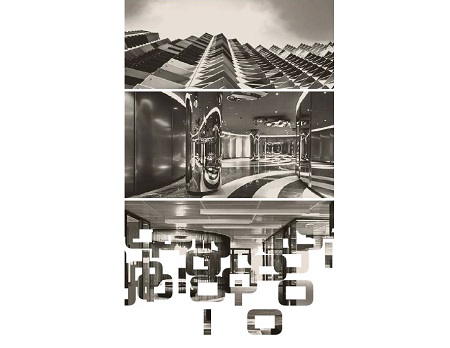

In 1995, Sapphire moved in to its new state-of-the-art manufacturing facility in Somersby, NSW. The new facility allowed Sapphire to provide its finishes for exterior use markets and expand into providing coatings for other new markets. Reducing delays associated with bespoke orders

In 2011, Sapphire went through an engagement process to replace their existing computer system.

"Our primary decider in selecting a new system was the ability for us to be able to find a configurator product," said Clynton Husband, managing director at Sapphire Aluminium.

"The people that came to see us from Epicor were manufacturing specialists. They knew manufacturing; they just had to tweak their idea around to our manufacturing process."

The Epicor Product Configurator is a configure-to-order (CTO) system that accelerates the transfer of knowledge from engineering to sales and manufacturing by predefining models, options, conditional rules, Bill of Materials (BOM), routings, and pricing.

For Sapphire Aluminium, reducing the delays associated with engineering each bespoke order was of great importance. By promoting standardisation, the Product Configurator increases product variety and decreases production variability by reducing the number of custom-engineered orders.

"The challenge with bespoke finishes is that is it very difficult to provide a generic cost because it is not a generic product," says Husband.

"We need to be able to go right through how we hold that product, how we colour it, how we package it and how it gets back to the customer, so having a facility to be able to do this when quoting is vital to us."

Leveraging Epicor to better support customers

A customer relationship management, or sales management system, linked to the Product Configurator enables sales or customer service reps to make quick determinations on the company's ability to deliver the exact product a customer is requesting.

"Epicor helps us to deliver to our customers a quality product that enables us to stay competitive in the market today and into the future," says Husband.

"Using the Epicor configurator and its combination of dashboard and scheduling tools, we are able to quickly identity where we can maximise efficiency to meet client deadlines."

When the configurator is part of a fully integrated ERP system, the rep can also tell the customer whether the parts required to build the product are readily available, and if the company has the available production capacity to fill the customer's order in a reasonable timeframe.

"Communication is critical to customers; knowing when they are going to get something, what it is going to cost, and is it on time, are vitally important to people in the building industry where they are on short lead times," says Husband.

"Epicor allows us to break down our projects into bite size chunks, so we are able to first of all cost the product, put in customised comments within the configurator that allow each production step and operation to be broken down and understood by the people that are doing that operation, and then put that back together into a story that's conveyed to our customer; so that they also know what we are doing and when it is going to happen."

Leveraging the Product Configurator for planning and scheduling production

The Epicor Product Configurator helps users standardise processes which can then be utilised by multiple people across the business.

The tool lets Epicor customers work smarter and remove some of the wasted effort when costing, planning, and scheduling jobs.

Husband explains the configurator's role in Sapphire's production process: "The configurator allows us to put the product in and do all of our costing and all of our job planning at the start when it should be done.

"Part of the Epicor system is developing a schedule in which we know when our product is due to run, how much of it we have on any given day, a week, a month. It allows us to easily move that production around so that we can consolidate the same finishes together.

"It certainly consolidates margins because we can accurately predict what we are going to put in the load, and when, which means we are able to maximise the production output and we can track costs which we couldn't do before in our old ERP system."

The configurator tool is designed with a rules-based system targeted to users in the sales and engineering area.

"It has some rules that are set up, and part of that rule system is the soft coding rule, so we can change the rules – it's not hard coded," says Husband.

"With the configurator, that's where we get the bang for our bucks because you're not re-engaging a computer programmer as your system changes or your requirements change."