Introducing the Eco-Controller!

Protoblast has always strived to help customers realise the best return on investment on their Abrasive Blasting Equipment and with rising energy prices we continue to pay special attention to the management of power consumption. With that in mind, our aim was to produce a device that would make a real difference to the power bill while keeping the operation as simple as possible.

Already aware of the potential savings of running large motor abrasive recovery and blasting systems like the dust collector fan motor with a Variable Speed Drive (VSD), there was enough evidence to look into how this could be used to save energy use in our Blasting Chambers.

So what is a Variable Speed Drive? Also known as a Frequency Converter, Variable Frequency Drive or an Adjustable Speed Drive, it is an electronic device which controls the motors electrical supply. Therefore, the speed and torque of a motor can be controlled to better match the process requirements.

Here is an example of how a Variable Speed Drive can save you thousands of dollars each year:

The Dust Collector Fan Case Study

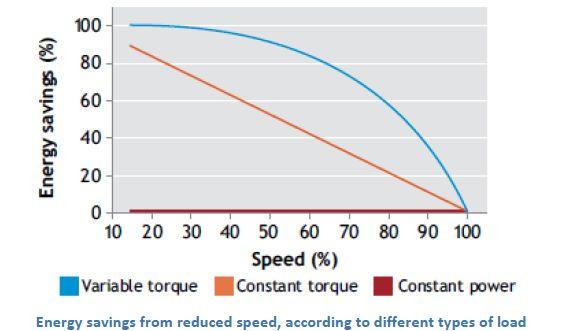

The load on a centrifugal dust collector fan is a variable torque load so the graph below shows that if full speed is not needed and the fan runs at 80% speed the power consumption is less than 50%. If we take the example of an average size dust collector, using an 18.5kW electric motor which uses 18.5kW/hr or 18.5kWh at full speed in a 6hr/day by 5 days per week this totals 555kWh/week. If this was reduced to 80% of full speed it would be 277.5kWh/week and at a rate of $0.26/kWh – a saving of $72.00 per week or $3,600.00/year on a 50 week year.

The other saving when using a VSD is on start-up of the motor. A standard Direct On Line starter will draw up to 800% of full load current on start-up whereas with a VSD will be 10% maximum. Not only is there power saving in this, but it means that the wiring size can be reduced and in the long run this can be significant.

The power saving solution

So with all of this in mind the Team at Protoblast have put together what we call an Eco-Controller for our Blasting Chambers. This controller utilises a VSD for the dust collector fan motor and a simple Programmable Logic Controller (PLC). With the Eco-Controller we have;

- Simplified the start-up procedure

- Totally automated the shutdown

- Connected a switch from the Dead-Man control to signal to the PLC when the blasting has started or stopped allow the system to auto shut down if unsupervised

- Ensured speed and times are all adjustable to suit the different needs of the customer as every site is different

Contact us now to find out what savings you can make!