Diagnostics solution raises condition monitoring to a new level

In order to even further increase system safety when handling magnesium, the light metal foundry Leicht metallgießerei Handtmann has equipped four new die casting machines with the PROFINET diagnostics solution TH SCOPE and TH LINK by Softing Industrial Automation. This solution monitors several fieldbus networks and protocols at the same time so that consistently high, overall network stability can be guaranteed.

Since it was founded more than 140 years ago, Handtmann has developed from a small manual brass foundry into an international group which processes all commonly used aluminium and magnesium alloys. Handtmann is still an independent family company and employs more than 3,600 staff at its headquarters in Biberach an der Riss, as well as at its factories in Annaberg, Kosice in Slovakia and Tianjin in China. In the 2017 financial year, the Handtmann Group generated revenues in the region of EUR 880 million. The business unit Light Metal Foundry made a key contribution to this success (EUR 625 million) as a system partner for the automotive industry and general mechanical engineering.

In 2015/16, Handtmann invested around EUR 25 million into building a new production site at Biberach where magnesium components are manufactured. Four new ultramodern machines with 2,500 and 1,800 ton closing pressure were added to the equipment used until now, which consists of cold chamber die casting machines; more than 45 of these are in use at Biberach and a total of more than 80 at all of the four sites taken together. Magnesium as a light metal material has a number of benefits, particularly for automobile construction: It is much lighter than aluminium so that fuel consumption is reduced, and emissions are lowered. The high cushioning effect means fewer vibrations and less noise, and the components themselves can also be produced in a much more energy-efficient process. “Compared to aluminium, however, handling of magnesium is not without its problems,”

Holger Scho¨llhorn, from the Equipment/Automation and Services (AS) department at Handtmann, points out. For instance, the liquefied material must not come into contact with air. Otherwise, there is a risk that it might ignite and cause a fire. Contact with water can even lead to explosions in the worst-case scenario. Accordingly, the fire safety requirements are high, and the building itself needed to be constructed from heat-resistant concrete.

All networks under constant observation

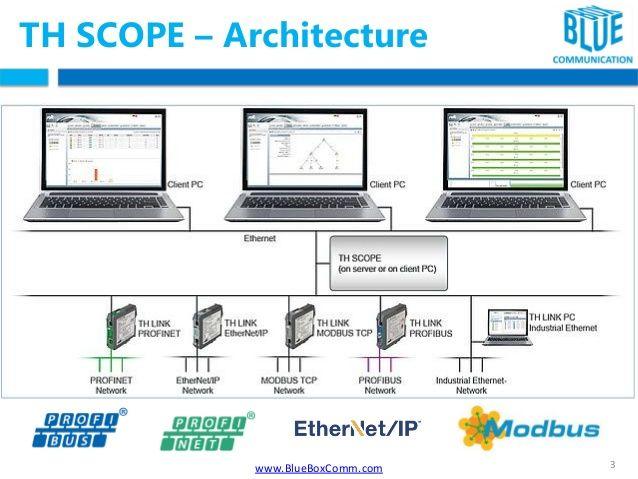

Since the new die casting machines were commissioned, Handtmann has been using PROFINET, the open Industrial Ethernet Standard for Automation. The diagnostics solution TH SCOPE and TH LINK by Softing Industrial Automation from Haar opens up further opportunities of condition monitoring. This is an integrated software solution for continuous status monitoring and predictive maintenance, as well as for approval measurements and fault localization during disruptions. As part of this process, TH LINK records the relevant data in the IP networks for up to 253 participants and makes these available to the user via TH SCOPE. The module can be integrated into both the existing machine pool and into new equipment.

“For us, it was important to utilize all conceivable potential in order to be able to ensure the highest possible system safety level when casting magnesium,” Holger Scho¨llhorn explains. “Consistent transparency and ongoing monitoring were relevant in this context. At the same time, we are using the opportunity to familiarize ourselves with the latest generation control components so that we can use them with full confidence, including for other die casting cells in future.”

Varied opportunities in only one system

TH SCOPE is aimed both at machine operators and maintenance personnel. Together with the TH LINK components, the product supports all commonly used network protocols, in addition to PROFINET. “The application can be flexibly integrated into existing systems and processes and is very easy to use so that you need no specialized network knowledge,” Anton Winkler, Field Application Engineer at Softing, reports. It offers stationary and mobile access. All diagnostics data can be exported and processed further e.g. in Excel. “In addition, fault and network statistics can also be generated for historical data or for any defined timeframe,” Anton Winkler continues. If the data recorded on the industrial network are e.g. stored on an SD card, they also remain available for analytical purposes or for fault-finding if the machine e.g. suffers temporary power outages.

The new production hall was fitted with four ultramodern die casting machines.

The PROFINET diagnostics solution TH SCOPE and TH LINK observes the whole network as part of status monitoring.

The decision to use the PROFINET diagnostics solution TH SCOPE and TH LINK was based on several criteria. Holger Scho¨llhorn explains: “We particularly liked the one-component system, which is uncomplicated and does not require expensive servers or component hierarchies in the field.” The cooperation with Softing during the introduction, parameterization and commissioning was also extremely constructive. “Softing is a company that assists you from the ground up and that knows what it is talking about,” the planning and implementation employee confirms. “You get help quickly, cooperate on a level playing field, and that makes it very comfortable.” The practical training sessions were also seen as very positive.

Ready to face changes

Image is that any hardware downtime does not result in major costs, the company explains. You are basically working with a Lego-like system, and this also makes maintenance easier. The implementation, parameterization and commissioning of TH SCOPE and TH LINK were completed within one week.

Since then, Handtmann has benefited from constant, web-based monitoring including an alarm system and consistent availability across different protocols. The PROFINET diagnostics software combines all the functions required for monitoring and analyses in only one system. At the same time, statistics and documentation from the connected networks can be displayed. Holger Scho¨llhorn summarizes the uses for his company: “Safety, loggability, change monitoring.“ He considers these factors to be even more important now than ever, especially given the explosion risks involved in handling magnesium, and the continuous increase in data.

“The greatest benefit of TH SCOPE is that several Fieldbus networks and communication protocols can be monitored at the same time using just one application,” adds Anton Winkler from Softing Industrial Automation, who provided technical support during project implementation. In the event of faults, the user is automatically sent advice on how to eliminate the fault. Furthermore, the network status can also be used as a reference for future comparisons.

The plan is to equip all of Handtmann‘s die casting machines with the PROFINET standard in future in order to be able to consistently generate added value. It is also conceivable that additional TH LINKs may be used which know their way around the entire network and active safeguard against downtime at all levels in their role as agents.

Author: Christoph Scholze, freelance journalist

Copyright © 2018 Softing Industrial. All rights reserved.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.jpg)

-205x205.jpg)