Corrosion is a persistent challenge for industries that deal with sensitive equipment and materials. Corrosion not only compromises the performance and lifespan of equipment but also poses significant financial and safety risks. Among the various factors contributing to corrosion, humidity and moisture are primary culprits. In this article, we will explore how humidity and moisture lead to corrosion and rust, and discuss the importance of proper indoor climate control through the utilisation of dehumidification technology.

Understanding the Impact of Humidity and Moisture on Corrosion

Humidity refers to the amount of moisture present in the air, and it plays a crucial role in the corrosion process. When relative humidity (RH) levels exceed certain thresholds, the air becomes saturated with moisture. This excess moisture can condense on surfaces, leading to the formation of water droplets. The presence of moisture creates an ideal environment for corrosion to occur.

Corrosion, often referred to as rust, is an electrochemical process that involves the oxidation of metal. When metal surfaces are exposed to moisture and oxygen, a reaction takes place, resulting in the formation of metal oxides or hydroxides. This process weakens the structure of the metal, leading to pitting, cracking, and eventual failure.

The Role of Proper Indoor Climate Control

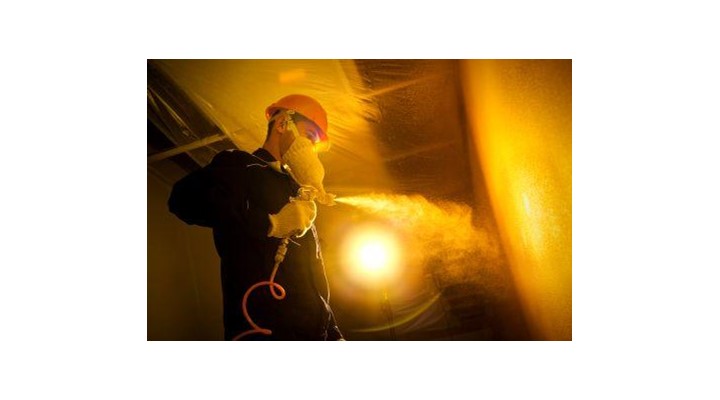

Maintaining proper indoor climate control is vital to mitigate the risks of corrosion. By regulating humidity levels within specific ranges, industries can effectively prevent the onset and progression of corrosion. This is where dehumidification technology plays a pivotal role.

Dehumidification Technology - The Most Effective Solution

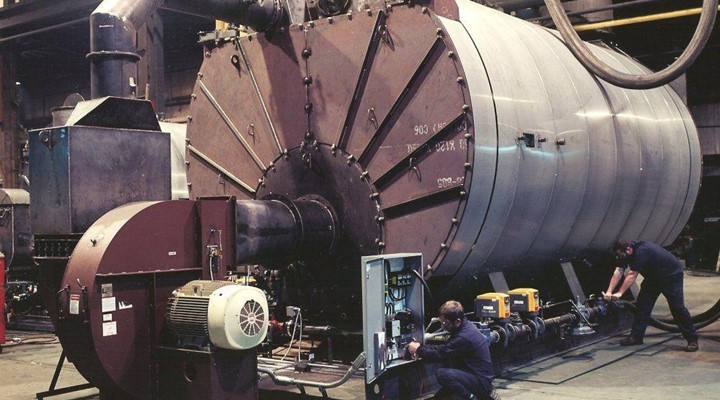

Advanced dehumidification technology offers an efficient and reliable solution for controlling humidity and preventing corrosion. These systems are designed to extract excess moisture from the air, ensuring optimal humidity levels are maintained in the manufacturing and storage environments.

BENEFITS OF DEHUMIDIFICATION TECHNOLOGY

By reducing humidity levels, dehumidifiers create an inhospitable environment for corrosion to develop. By controlling moisture, they effectively safeguard equipment and materials against the damaging effects of rust.

Increased Equipment Lifespan:

Corrosion significantly reduces the lifespan of equipment and machinery. By investing in dehumidification technology, industries can extend the operational life of their assets, resulting in substantial cost savings over time.

Improved Product Quality:

Moisture can negatively impact the quality of products, leading to defects and compromised functionality. Dehumidifiers help maintain optimal conditions for manufacturing processes, ensuring consistent quality and reducing product rejections.

Enhanced Safety:

Corrosion compromises the integrity of equipment, posing safety risks to both personnel and the surrounding environment. By implementing dehumidification systems, industries can minimize the likelihood of equipment failures and accidents, promoting a safer workplace.

Humiscope: Leading Experts in Corrosion Prevention

We work myriad industries that deal with sensitive equipment and materials from bridge preservation and power generation plants to food processing and sensitive material preservation.

We also offer short and long term dehumidifier hire for clients with temporary projects or whose processes suffer from seasonal changes.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)