Facilitating innovation

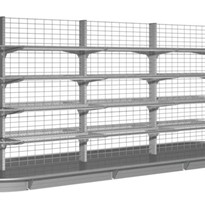

Theebo Tech Pty Ltd started on a small farm outside Hopefield, a town on the west coast of South Africa. It is the sole developer and manufacturer of Equalizer agricultural implements. Its featured products include the Min-Till Precision SL Planter, Wide Span Precision C Planter and Min-Till Air Seeders. Theebo Tech serves South Africa and the international agricultural equipment market.

“One of the components that has given us the ability to be more innovative is Solid Edge,” says Theodore Turner, who is the head of design and development at Theebo Tech.

Twelve years ago Theebo Tech selected Solid Edge® software from product lifecycle management (PLM) specialist Siemens PLM Software. The company’s decision was largely based on the ability of Solid Edge to support sheet metal and large assemblies, and the company remains very pleased with that decision. With Solid Edge, the assemblies consist of every single nut and bolt, and from there engineers can pull the build material that goes into jobs on the shop floor.

Managing risk

Now Theebo Tech is using the Solid Edge™ SP design management solution (Solid Edge for SharePoint® software), which provides easy vaulting and retrieval of Solid Edge files and related design data, along with a visual approach to managing linked documents, product structures and projects.

The company is using Solid Edge SP to simplify and automate error-prone processes, such as new product introductions, engineering changes and release to manufacturing. This straightforward approach to managing complex data simplifies the design process, enabling Theebo Tech to meet and exceed its targets for design project completion.

“Although we have a diverse product range, we try very hard to keep our designs modular, and Solid Edge for SharePoint allows us to re-use our designs very easily and accurately,” says Turner.

One of Theebo Tech’s biggest concerns was managing the risk and impact associated with design changes. Utilizing the visual approach of Solid Edge SP, the company now finds it significantly easier to see the links between files and the impact of design changes.

Visualizing relationships

To ensure product quality, Theebo Tech needs to be able to provide the appropriate personnel with the necessary documents at any time. With Solid Edge SP, documents are placed in one container, so there is no need for users to go search for documents. This resulted in significant time savings.

Turner also noted that Solid Edge SP is unique in that its part container allows other information to be embedded in the same container. This makes it very easy to find other engineering information, supplier drafts and test results by simply searching the specific part form.

“One of our favorite features of Solid Edge SP is the relationship browser,“ says Turner. “It makes it so easy and simple to visualize all the relationships between CAD files, engineering change requests, engineering change orders and projects.”

Accelerating design

Theebo Tech particularly appreciates the synchronous technology functionality of Solid Edge, which enables users to easily and quickly modify a complex part. Instead of using the traditional manner of going in and finding the actual part, changing it and problem solving down the history tree, now a user simply amends the part and then starts the next part.

“We were able to go from design to finished concept on our SL Planter in literally three weeks, due mainly to the capabilities and ease-of-use of Solid Edge,” says Grant Parkes, senior designer at Theebo Tech. “Using Solid Edge, we’ve accelerated our design turnaround exponentially.”

“An unfair advantage”

“We feel that Solid Edge gives us an unfair advantage,” says Turner. “It’s such a powerful technology without the unnecessary complications that you too often get with larger programs, and it allows us to be competitive with bigger manufacturers even though we have fewer resources.”

Theebo Tech works with a number of associates to deliver its highly successful product line. One of the company’s important contributors is ESTEQ, the Siemens PLM Software partner that provides the firm with computer-aided technologies (CAx) consulting. ESTEQ assisted with the company’s licensing and implementation of Solid Edge.

Gideon Schreuder, managing director and owner of Theebo Tech, says that the use of Solid Edge has made a dramatic difference in delivering its products to market faster, more efficiently and with greater innovation. Schreuder notes that Theebo Tech’s customers are especially pleased with the quality and continuous advancements of its agricultural implements. He concludes, “Solid Edge plays such an important and integrated role in our manufacturing process that we can’t do without it.”

Challenges:

- Select design solution that can best manage sheet metal and large assemblies

- Streamline the design process

- Improve the re-use of 3D product data

Keys To Success:

- Understand the link between files and the full impact of design changes

- Enable ready access to critical documents

- Utilize synchronous technology to accelerate product development

Results:

- Notably improved design speed

- Significant re-use of designs from previous models

- Simplified and automated product development processes resulting in substantially improved operational efficiencies

- Products delivered faster and with greater innovation

Industry:

- Industrial Machinery & Heavy Equipment

Client’s Primary Business:

Theebo Tech is the sole developer and manufacturer of Equalizer agricultural implements in South Africa. Its featured products include the Min-Till Precision SL Planter, Wide Span Precision C Planter and Min-Till Air Seeders.

Solutions/Services:

- Solid Edge

- Solid Edge SP

Client Location:

Brackenfell, Western Cape

South Africa

“We feel that Solid Edge gives us an unfair advantage. It’s such a powerful technology without the unnecessary complications that you get with larger programs, and it allows us to be competitive with bigger manufacturers even though we have fewer resources.”

Theodore Turner, Head of Design and Development, Theebo Tech Pty Ltd

“We were able to go from design to finished concept on our SL Planter in literally three weeks, due mainly to the capabilities and ease-of-use of Solid Edge. Using Solid Edge, we’ve accelerated our design turnaround exponentially.”

Grant Parkes, Senior Designer, Theebo Tech Pty Ltd