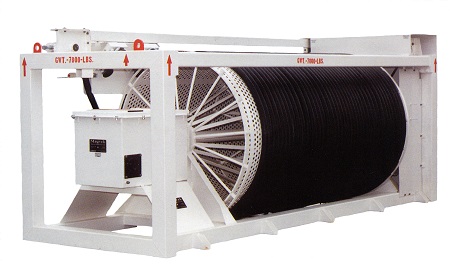

Large heavy electrical cables 50mm to 75 mm thick which run to mining equipment were being manually handled when laid and relocated. This resulted in safety risks including trip hazards, and physical strain injuries. The equipment designer developed a concept of a hydraulically operated cable reeler module which could be uncoupled and moved from one excavator to another.

The cable reeler turns to wind up the electrical cables and can also be released in order re-lay the cable. Custom Fluidpower developed a hydraulic system involving a hydraulic motor , hydraulic cylinder, manifold and hoses and fittings.

The Sai GM2 hydraulic motor's low speed high torque, high speed high torque capabilities, along with its ability to free wheel when re-laying the cable, made it the best selection for the project.

The circuit for the custom manifold was designed and manufactured by Custom Fluidpower at their state of the art machining centre.

The equipment designer expects a roll out of this innovative new equipment throughout the mining sector, due to its safety risk reduction capability and Custom Fluidpower looks forward to partnering with them through this period.