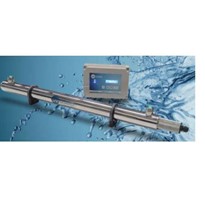

Here in Australia a leading brewer, Tooheys, made the decision to sterilise their process water with Hanovia UV supplied by Fluidquip Australia, and from the first system that was installed about six years ago they have continued to add more UV systems to various parts of their process. The first UV system installed was on the de-aerated water generation plant about 6 years ago, since then two Hanovia UV systems have been added to the de-aerated water distribution plant, one system added to the sugar intake and a further two systems after the carbon filter on the water inlet to the Brew House.

The brewer's Group Technical Managers needed to decide not only how to effect sterilisation of their water, they also needed to evaluate the range of commercial options.

Hanovia UV was chosen as the preferred supplier in this installation, even though they weren’t the cheapest option. UV sterilisation was identified as offering the following benefits to the brewing process "UV sterilisation is not going to impart a flavour; no chemical dosing is required; UV sterilisation is unlike Ozone, which may create a reaction with the brewing ingredients by reacting with the free radicals; sterilants or other chemicals and could potentially taint the beer; UV is seen as a clean way to sterilise the feed streams going into the brewing process."

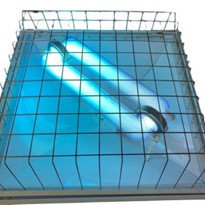

The sugar intake did present some particular constraints. Given the heat in the UV lamps can caramelise the sugar, and with the sugar running as a batch system (with start up and shut downs), it is necessary for the brewers to ensure there is a good flow going through the UV systems before the UV lamps are engaged. To avoid unsterilized product going past the UV system there are circulation loops in place, this avoids having standing product in the UV system whilst the UV intensity comes up.

When producing product under license, UV sterilisation can be required as close as possible to the point of use of the dilution water. Even in the absence of microbes, the use of UV sterilisation ensures all quality requirements are guaranteed to be met.