If automotive manufacturers use universal sheet metal processing systems in their production halls instead of press brakes, they could make their assembly process considerably more flexible while reducing costs.

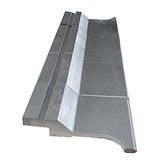

''The basic idea behind this concept is that the components for production are produced, formed and subsequently welded from smooth metal sheets using 2D laser cutting mavhines,'' explain Klaus Löffler, a TRUMPF specialist in automotive production technology.

Automotive manufacturers are currently facing a multitude of challenges. On the one hand, they have to comply with the legal requirements for the CO2 emissions of the cars they produce. On the other hand, customers are demanding more and more of theirs cars.

Current trends point to built-to-order cars that automotive manufacturers have to lunch on the market in ever shorter product cycles. This also reduces the quantities in production during the service life of the car.

Read More (PDF)

Call Headland on 03 9244 3500 for more information.