The Water Services Association estimates it could cost approximately $15 billion in Australia alone to repair or replace the asbestos cement pipelines used in water networks, with half of this focussed on pipelines that are expected to come to the end of their lifespan over the next decade.

"The central issue in the pipeline network renewal task is not any health risk from drinking water passing through the pipelines while they are intact, but rather worker safety and community safety during the task of renewal," says James Maslin, Sales and Marketing Manager for Air Springs Supply Pty Ltd. "It is important in this regard that repair and removal technology touches lightly on the affected pipelines and does not contribute to damage or breakage."

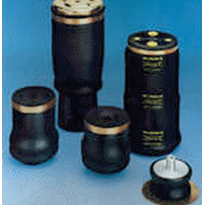

Air Springs Supply is the national distributor for the globally proven range of Pronal elastomer inflatable pipe stoppers, lifting cushions, seals, tanks and environmental protection products used by municipal, industrial, civil emergency and military forces to repair and restore environmentally sensitive services including pipeline networks.

Inflatable Pronal stoppers – equipped with bypasses where water supply must be retained while pipeline sections are replaced – are inflated to create a powerful, watertight and non-destructive seal to safeguard maintenance workers and preserve the integrity of networks. (www.pronal.com.au)

Pronal lifting cushions, meanwhile, provide a way to lift, shift and position old or replacement pipelines even in sandy trenches or on soft surfaces. The cushions – larger versions of which are powerful enough to lift railway locomotives and damaged aircraft – spread their lifting power evenly over a wide area, thus avoiding point loads that could damage object being lifted or cause instability and breakages.

"Pronal stoppers and lifters have been proven globally to address many environmental issues involving industrial and municipal pipelines of all types, including concrete, cast iron, steel, stainless steel and PVC. The issue of asbestos in cement pipes is not unique to Australia, but common to many countries, including North America and the UK," says Maslin.

"Pronal technology is used not only on water pipeline networks, but also their environmental credentials have been demonstrated in Australasia on industrial pipeline networks where their stopping efficiency, light weight and reusability are useful to manufacturers, miners and other big users of water and process solutions," said Maslin.

Pronal inflatable pipe stoppers are already in widespread use for maintenance, testing and emergency tasks in applications as diverse as industrial and municipal water and waste water, and pollution prevention in mining, energy and industrial projects where sealing and testing operations need to be conducted not only with complete safety and environmental security, but also with considerable speed, to maintain flows of liquids and gases.

The stoppers – most recently put into service Down Under with national food and beverage, defence manufacturing and chemical processing companies – can be rapidly deployed, easily transported and widely applied in remote, temporary and permanent industrial situations.

Their affordability and cost-effectiveness has expanded greatly as more are brought into service, says Maslin "Their local and global success means that increasing volumes and types are available at even more competitive installation costs than previously. Advantages of scale are also producing a broader range of stock types and sizes to fit pipelines up to 2115mm inside diameter and custom-produced models over 3000mm," he says.

The expanded ranges and greater cost-efficiency are particularly timely not only to address the asbestos issue in public water supply, but also for Australian industry because of the safety focus on preventing industrial spills. Safety is a major focus of State Environmental Protection organisations and of national bodies such as Safe Work Australia, which has introduced its Code of Practice for Managing Risks of Hazardous Chemicals in the workplace.

Risk Management

Pipelines are a particularly important component of risk management plans not only involving purity of water supplies, but also where companies may be handling increased quantities and types of hazardous materials associated with production and process engineering, cleaning, vehicle maintenance and plant upkeep, for example. In addition to potential hazards to people in the workplace, environmental authorities are particularly concerned about possible spillages of contaminated waste water into nearby streams, rivers, seas and groundwater systems.

The common factor with maintenance, testing and emergency situations is that they need stoppers that can be rapidly and securely deployed to provide primary or secondary safety and environmental security as required by both by Safe Work Australia and State Environmental Protection Agencies.

Sometimes stoppers are permanently located in pipelines for instant remote inflation with compressed air or other gas where there is a risk of toxic runoff at different stages of production, or where spillages occur. In other instances, they are used to seal off sections of pipe where leaks are occurring, serving the dual role of enabling pressurisation of that section so leaks can be detected, then protecting the men in the pipeline from any product flows while they work to fix the problem.

They are extremely strong and durable in service, being hot vulcanised in a mould to give outstanding service life. The material used in the stoppers and the production method (customised dilatability) means they are extremely versatile.

Pronal products are based on more than 40 years of producing specialist pneumatic elastomer designs for demanding applications, including government, military, heavy industrial, emergency service, sub-sea and exploration. Australian distributor Air Springs Supply also has more than 30 years specialist experience in applying pneumatic actuation and isolation technologies.

The big advantages of the technology also include simplicity, portability and re-use. Maintenance staff don’t need huge amounts of gear on-site and the stoppers themselves are easy to transport around plants to remote locations, where they can be used, moved on, and used again and again. They are an ideal method by which to achieve compliance with statutory requirements in a cost-effective and efficient manner.

LR-720x400.jpg)