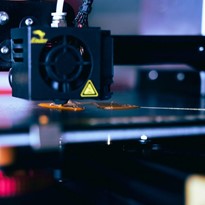

Benson Machines has been supplying machine tools to the Australian precision engineering sector for over 100 years, but has recently embraced the emerging technology of additive manufacturing, distributing Rapman 3D printers.

Sam Addison, Benson’s product manager for the Rapman range, told Industrysearch that the technology is being used by the educational, industrial design and hobbyist sectors.

So how does 3D printing work?

"It’s the process of fusing layers of materials together, it generally means your adding material and so it’s an additive manufacturing process as opposed to milling or grinding," Addison said.

"It adds to itself and creates an object from nothing rather than a big block of metal and that’s machined away."

The professional sector in Australia is currently using this technology for rapid and cheap prototyping but additive manufacturing is being talked about as a manufacturing game-changer.

The Economist, in an article earlier this year, places additive manufacturing in a line of world changing inventions from the printing press to the transistor and points out that an entry level 3D printer now costs less than a laser printer did in 1985. Cost is no barrier then.

According to Addison the technology is not quite there for the production runs of end parts just yet.

"It’s not that mainstream at the moment. It’s used for prototyping and rapid manufacturing, it’s a fast and cheap way to produce lots of different parts," Addison said.

He said the hobbyist market was already using the technology to make end parts for remote controlled models – be it replacing a broken helicopter part or customising an existing part.

A modeller can call up a blue print on his computer, tweak it and simply press print. But what are the more profound implications of this technology?

According to The Economist, large, high-end 3D printers are being used to make finished parts in the automotive and aerospace industries at costs that are competitive with plastic injection moulding for smaller production runs.

Although additive manufacturing is no faster than conventional manufacturing it has one great advantage – there is almost no waste.

"To generate and print an object about the size of a cigarette packet - that would probably take a couple of hours", Addison said.

"The speed of the machine is on a par with a milling machine say, but you don’t get any waste material. In milling or routing you lose 40 per cent from your block of material. So your running costs are going to be a lot lower."

Additive manufacturing is very much in its infancy - rather like computing in the late 70s - but its potential nevertheless is limitless.

"At the moment they’re [3D printers] not really high-end enough for professionals in terms of tolerances and the complexity of the parts you can make. You’re a bit limited as you can’t print off a working part. You’d have to print multiple parts and put them together later," Addison said.

"But this technology is always changing, always getting better."

Bits from Bytes, in the UK, manufactures the Rapman range of 3D printers.

(1)-205x205.jpg)

(1)-205x205.jpg)

(3)-205x205.jpg)