The latest Smith and Loveless PISTA® 360™ technology – which removes 95 per cent of grit as small as 105 microns – eliminates the build-up of grit in downstream aeration basins and sludge digesters.

The technology is particularly relevant to councils and utilities serving the more than 80 per cent of Australia's population living within 50 km of the coast and more than 72 per cent of New Zealanders living within 10km of the coast, often in sandy areas.

It reduces damage to downstream equipment from abrasion, enhances WWTP reliability, reduces OH&S hazards involved in unclogging systems and helps to prevent environmental spills from blocked and flooded systems.

"PISTA® technology has set the global benchmark for grit removal for many years. It far exceeds the established standard for grit removal, which has been 95 per cent removal at 250 microns. We are now achieving the same removal efficiency at 105 microns (140 mesh), this latest technology sets an entirely new benchmark," said Michael Bambridge, Managing Director of CST Wastewater Solutions.

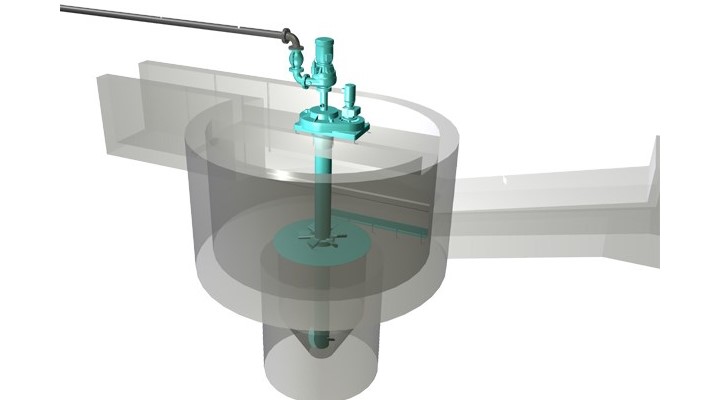

The latest PISTA 360 uses an integral flow chamber baffle for both the inlet and outlet of the main chamber. The baffle is designed to direct the inlet flow into the chamber in a manner that ensures the proper vortex flow and prevents short-circuiting.

The V-Force Baffle™ allows for a full 360 degrees rotation through the inlet and outlet, providing maximum travel of the wastewater for the most effective grit removal before proceeding to downstream treatment processes. The baffle acts as a "slice weir" to control the water level in the main chamber and in the inlet channel. A 10:1 turn down in performance is achievable with this the system.

"This innovation further enhances the world's best grit removal system from PISTA®, which incorporates many engineering and cost saving considerations," Bambridge said.

"By increasing chamber velocity during low flow periods, the baffle extends the grit extraction path within the vortex grit chamber. This is the key, because a longer path increases the amount of grit being captured on the chamber's flat floor."

Design flexibility

The PISTA 360™ with V-Force Baffle™ permits design flexibility so that water elevations can be controlled. "Water level control is important because it upholds the proper velocities approaching the grit chamber," he said.

"Previously, the common way to accomplish water level control was to back up the flow with a downstream submerged weir. The PISTA 360™ with its preset inlet and outlet openings supplants the need for the submerged weir.

"By integrating the water elevation settings with the baffle, the outlet footprint requirements decrease by as much as half the typical size. The resulting smaller footprint provides significant construction cost savings."

Benefits of the V-Force Baffle™ include:

- 95 per cent grit removal efficiency down to 140 mesh particle size.

- Construction cost savings due to decreased overall grit system footprint.

- Increased grit chamber velocity during low-flow periods.

- Full 360 degrees rotation in the chamber, lengthening the grit extraction path.

- Elimination of the need for downstream level control devices.

- An ability to handle a wide range of flows.

The PISTA® 360™ with V-FORCE BAFFLE™ with its pre-set inlet and outlet openings supplants the need for the submerged weir.

CST Wastewater Technology packages

New engineer-and-build water and waste water treatment and recycling packages from CST Wastewater Solutions are aimed at industries and municipalities that want to lower the cost and complexity of such projects.

The design, supply and install packages – incorporating global and locally manufactured technologies proven in use by some of Australia and New Zealand's leading companies and councils – are aimed particularly at:

- Councils seeking engineering assistance to develop clear choices and optimum solutions incorporating advanced low-maintenance technologies providing high levels of water purity while reducing maintenance, waste handling and OH&S issues associated with running them.

- Industries seeking readily constructed or portable, low maintenance solutions for operations particularly in remote, ecologically or environmentally sensitive areas - ranging from resources or agribusiness developments in the country or outback, through to food, beverage, manufacturing and processing plants sharing precious water resources with urban areas.

Rather than presenting such organisations with a jigsaw of disparate collections of technologies and engineering services options for them to piece together, the packaged solutions focus on clear, properly engineered solutions that deliver what they promise. CST offers turnkey solutions based on a known raw water quality and guaranteeing water quality outcomes thus giving user engineers significant confidence in the outcomes and limiting their exposure and potential concerns, says CST Wastewater Solutions Managing Director Michael Bambridge.