Although it was originally proposed in the early 1950s, nowadays printers are programmed to create models determined by computer-aided design (CAD) software.

HOW DOES IT WORK?

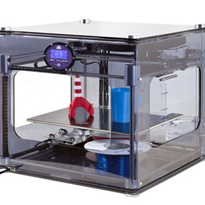

When it comes to 3D printing there are a few different types of technologies that could be used, each one with its own process and outcomes. Stereolithography (SLA) and Fused Filament Fabrication (FFF) are two of the most common technologies used in the prototyping and manufacturing industry

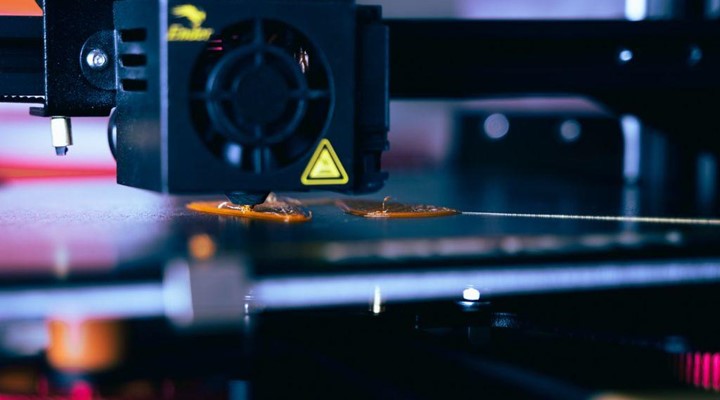

The FFF process uses a thermoplastic material in the form of a filament wound on a reel for ease of access and implementation. The material is then heated and extruded onto a platform into a predetermined pattern to create the desired masterpiece.

Alternatively, the SLA process works by concentrating an ultraviolet laser on photopolymer (light-activated) resin to solidify a shape on the surface of the resin chamber. This process is then repeated layer by layer to create the final intended structure, much like the FFF process.

WHY DOES INNOVEC USE IT?

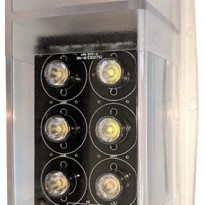

Throughout our history Innovec Controls has been a pioneer in offering custom LED lighting solutions for railway rolling stock. From our very first module, the Millennium Light, to the LEDEL - a brand new engine room light.

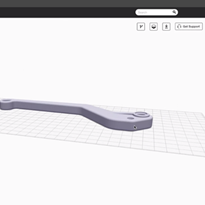

We include you into the design process so that you can have a product that is application specific.

Over the last 12 months Innovec has ventured into 3D printing technologies, for the main purpose of prototyping. We are now using this knowledge to provide our clients with the unique experience of working prototypes that they can test and feel in their own hands.