Deprag, Germany are manufacturers of a large range of high quality pneumatic air motors. Deprag's extensive range consists of hundreds of standard motors from 80W up to 18kW. These motors include gear motors, sealed motors, brake motors, high torque motors, ATEX approved motors and stainless steel bodied motors. Deprag are also flexible enough to manufacture custom built motors in case the standard motors do not suit your application.

Pneumatic motors can be used for the following situations:

- When explosive dust or gases are present – air motors are a generally safe drive and do not normally throw sparks or get hot when overloaded. ATEX approved motors are available.

- When the environment is wet or very dusty – air motors do not require external air to cool them and are sealed so water or dust will not get inside.

- When the motor will stall – air motors are not damaged and will not overheat by stalling, once the load is removed, they will start up again.

- When space or weight is restricted – air motors can be up to 1/5th the weight and 1/3rd the size of an electric motor

- When a high start torque is required – air motors have a high start torque and can be started and stopped repeatedly without damage

How to save time and money when choosing and utilising air motors:

- Get the specification right.

- What is the operating environment?

- Are hazardous environment approvals required?

- Brake modules – how to hold a load in position?

- Preventative maintenance prevents unplanned downtime.

Specifications

Selecting the right motor first time saves a lot of messing around. The starting point for any motor selection is the required speed and either the power of the motor or the torque required. The other factors need to be considered, for example, air consumption, service life, start torque, stall torque and shaft loading.

When comparing motors from different manufacturers, it is necessary to check that the specifications are all made at the same air pressure. A 1kW motor rated at 6bar will have 20 per cent more power than a 1kW motor rated at 7bar.

Speed

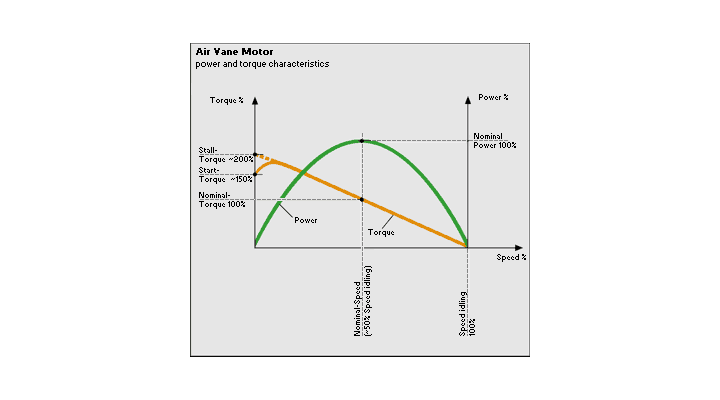

An important consideration in choosing an air motor is the fact that an air motor’s speed will slow according to the load applied. A 1200W air motor may have a no load speed of 9000rpm, but the power will be measured at the nominal speed of 4500rpm. Depending on the load, the working speed could be as low as 500rpm. To correctly determine the final speed, we need to know the working torque.

The motor’s final speed can be changed by using a combination of gearing, pressure regulation and throttling. The use of a motor with integrated gearing can often be cheaper than using a motor coupled to another brand of gearbox. Check both options.

Air consumption

When comparing different air motors, always check the air consumption. Compressed air can be expensive and over the lifetime of the motor it can pay to use the most efficient motor possible.

Careful motor selection can also reduce air consumption. Firstly the smallest possible motor should be chosen, secondly the closer the motor’s speed is to the stalling, the less air it will use. If necessary, reduce the motor's speed by throttling the air flow rather than reducing the air pressure.

Shaft loading

It is important to check if the radial or axial loading on the motor shaft is within the manufacturer’s guidelines, otherwise costly premature bearing wear and possible gear damage can be expected.

Shaft Type

Other than the standard keyed shafts, some manufacturers offer other options. Deprag offer threaded, tapered and even collet shafts on many of their motors and short runs of special shafts can be accommodated.

Service Life

If the motor is going to be used constantly, correct motor sizing can increase the time between service intervals. In general a motor should be chosen so that it is oversized as well as running near its nominal speed for maximum lifetime. If necessary, the speed should be reduced by throttling the air flow or reducing the air pressure.

Operating Environment

Perhaps the most common use for air motors is in hazardous environments, where the risk of explosion is present, however other conditions should be considered.

Is the environment wet or dusty? Most air motors are well sealed so water and dust will not damage them.

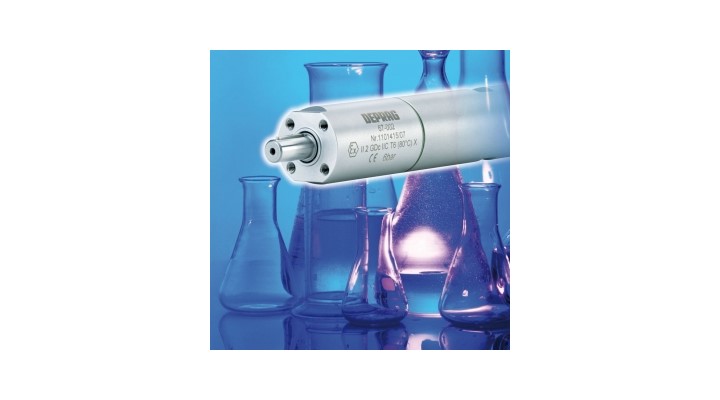

Could the motor be submerged in water or even acid? Consider specifying a stainless steel bodied motor. We recently supplied high grade stainless steel motors with extra seals to stir sulfuric acid for a mine.

Will the motor need to be washed down (eg food industry)? Deprag have a standard range of stainless steel motors suitable for wash down.

Could a grease leakage contaminate the product? We recently supplied motors for juice manufacturer with USDA approved food grade grease, extra seals and a seal failure indicator.

Hazardous Environment Approvals

Air motors are well known for being a safe drive choice in potentially explosive environments. They normally do not overheat or "burn out" and do not throw sparks.

Many engineers use them in hazardous areas without a second thought. We all know a risk assessment should be done on any piece of equipment going into a workplace; however we see people automatically assuming that all air motors are safe.

If the work place is likely to have an explosive atmosphere due to dust or gases, the use of ATEX approved air motors will give the risk assessor a higher level of confidence about the motor.

The ATEX approval is a European standard for equipment that is used in explosive atmospheres. To use the approval, the manufacturer has to supply motors and operating instructions to an independent testing facility.

The motors are then tested and rated according to their maximum surface temperature. Information about recommended maintenance intervals and surface temperature testing must also be included in the operating instructions.

Brake Modules

A common method of stopping or holding a load with an air motor was to supply air to the forward and reverse ports of the motor. This has two problems. The first is that while both ports are supplied with air, the motor is wasting expensive compressed air. The second is that if the air supply is lost, the load could fall or move causing injury or damage to the machine.

The other option is to use a brake. If a load needs to be held in place for a period of time, it is cheaper and neater to use a motor with an integrated brake module, rather than adapting a brake to the end of a motor. Brake modules usually fit between the air motor and gearbox and engage when the signal line drops below a certain pressure. Deprag offer a range of 200, 300 and 1200W pneumatic brake motors.

Preventative Maintenance

Preventative maintenance will save downtime and money. One of the advantages of air motors is that they can be safely serviced by a mechanical fitter. If motors are not maintained correctly, the resulting damage will be far more than the small amount of time invested to keep them in good condition

Lubrication

Correct lubrication is important. Good air motor oil should be resin free, emulsify water and include a rust inhibitor.

Many manufacturers offer lubrication free motors, but the fact is that if lubrication is not used, the maintenance intervals will be higher and the air must be very clean and dry. Any dirt or water contaminants will severely affect the motor if lubrication is not used.

Regular Maintenance

General statements on the frequency of maintenance and service intervals for pneumatic motors are hard to give, as there are quite a lot of important factors to be considered which are hard to calculate. The range of Deprag pneumatic motors is very large and many varieties are available, differing in their torque range, gear size, speed range, motor size, to suit all imaginable applications. So, the correct selection and use - of the motor are also vital for determining a service and maintenance interval.

For example: If the motor is used without lubrication, the maintenance requirement is reduced to 250 operating hours. In another case: if the same motor is well lubricated and used under best conditions, the maintenance requirement can be 2000 operating hours.

If you don’t use the motor for a longer time period, it helps a lot to lubricate the motor with a couple drops of oil into the air inlet and let him run for 5 to 10 seconds. Also a collapsed bearing or dried out grease can result in expensive damage to the gears, as well as the inconvenience of unscheduled machinery down time.

Access to the Motor

Given that regular maintenance is recommended, how easy is it to remove the motor from the machine for servicing? And how long does it take to service the motors?

Deprag offer a range of motors where the vanes can easily be changed without removing the motor from the machine or pulling the motor apart.

By using an Allen key and tweezers it is possible to exchange the vanes in the shortest possible time and by untrained personnel. Therefore disruption of valuable production time is considerably reduced.

We have a range of air motors and can assist you with your needs, for more information please call or email us for a direct reply.

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-160x160-state_article-rel-cat.png)

-205x205.jpg)