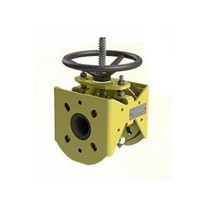

The Upwey MAXI-Check I combination Ball Check and Isolation Valve is an ideal option for plant designers and operators needing a commercially available abrasion and corrosion resistant check valve and isolation valve, for relatively high (20, 50, 100 or 150 bar) pressures associated with pumping of turbid water from open-cut or underground mines.

The conventional approach

To allow pump maintenance to be performed safely in any situation, requires that connected pipe-work is either emptied of fluid or provided with positive isolation in the form of gate valves -one adjacent to the pump discharge and in the usual case, where the pump is fed from an elevated tank or reservoir, another gate valve is also installed upstream of the pump intake connection. In addition to this, it is common practice to install a self-actuating swing disc check valve between the pump discharge connection and the discharge isolating valve, in order to prevent any back-flow of liquid following a pump stoppage, and to allow unattended and/or automated pump starting and stopping.

The 'Upwey' approach

As shown in the cutaway photograph, the Upwey MAXI-Check I valve combines the back-flow prevention function of a ball check valve, with a hand-wheel operated or auto-actuated spindle and ball retaining yoke mechanism. In this way, the twin functions of an isolating valve and a check valve, are provided in one single product.

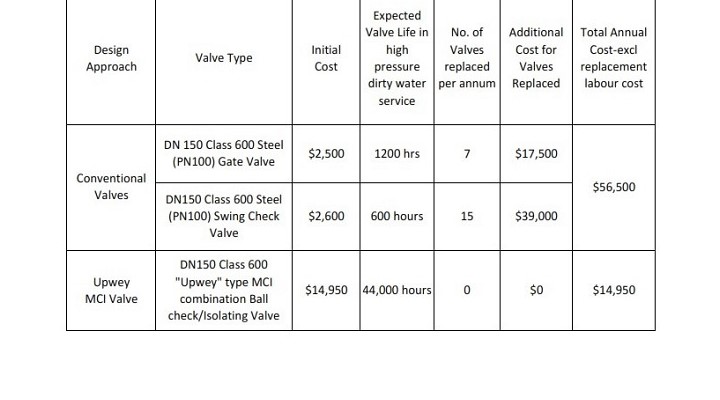

Lifecycle cost comparison

Although the conventional approach is the cheapest solution initially, it’s also the most costly in the longer term, especially when pumping clean or dirty water from deep underground to the surface. In such situations, whenever a fixed speed pump is stopped, the inertia of check valve disc prevents it from closing until reverse flow "slams" the valve closed.

Although this all takes place in a 'split-second', the slamming of the valve disc sets up severe pressure transients (water hammer), which at best cause premature failure of the valve, and at worst, cause flooding and costly damage to other equipment or injury to personnel.

It was this very situation, exacerbated by the erosive effects of sand in the underground water, causing leakage across valve seats, which over the last decade, has led one leading Australian underground miner to replace scores of check/gate valve installations (commonly in size DN150) with Upwey MAXI-Check I valves.

Based on this scenario, the above table compares the total lifecycle (capital + maintenance) cost comparison, for various types of check valves and isolating valves, with the Upwey MAXI-Check I Valve. (indicative prices used)