Its features include:

- a toughened windows based tablet to provide high speed processing and analysis of the correlation data

- low frequency transmitting sensors for trunk mains

- antenna stands to maximise radio communication to distances over one kilometer

The Aquascan TM was tested in a number of known leak sites in Manila. The objective was to enhance its performance in busy Asian Cities with large levels of background noise, even in the middle of the night. All of the field testing was performed at night and all of the sites were residential or light industrial areas.

All of the testing performed here was with Accelerometer sensors making a magnetic connection to the valve or gauging point. We believe better results will be achieved using hydrophones.

Figure 1 shows the first result – the possibility of one or two leaks at Tanza Bridge. Sensor A was deployed on the gauging point near the market. Sensor B was deployed next to the gauging point at the top of the bridge. The main peak of the correlation is at exactly the same place previously indicated by the correlator during our demonstration in October 2009, i.e.: 107.3 meters from the gauging point by the market. This indicates the following possibilities; a) the pipe has split again due to the weight and stress caused by trucks travelling over the bridge, b) the leak was not repaired correctly or c) there is an object inside the pipe creating significant turbulence noise.

The second peak is 97 meters from the gauging point by the markets and definitely worth investigating. Due to the changes in depths, bends and directions of this pipe to circumnavigate the bridge, I do not have 100% confidence in the overall length measurement. It would be no surprise if the actual leak position was a few meters either side of the positions indicated in these results. It is highly recommended that a team investigate this site.

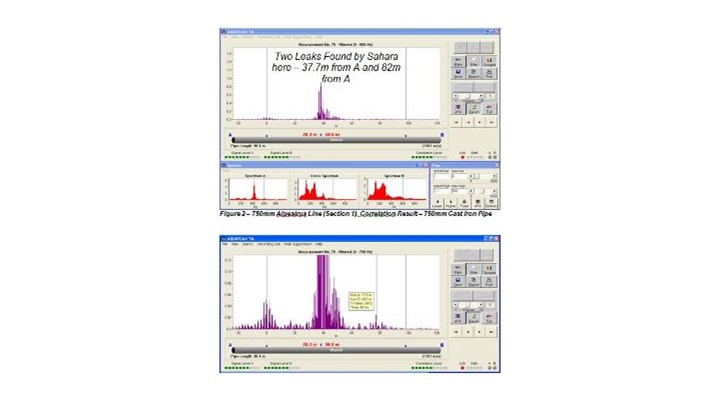

Leak noise correlators can detect multiple leaks. The leak is displayed graphically as a noise signal. When one leak signal is significantly greater than the others, the second leak does not look like a leak on the graph. A prime example of this is shown in Figure 2 and 3. In the field, after correlating, locating, pinpointing and repairing a leak it is common practice to return to perform an additional correlation to see if there are additional leaks.

The peak shown in Figure 2 on the 750mm Algesirus line is close to a bridge. Sensor A is deployed on a gauging point with an insertion probe flow meter attached. Turbulence noise is generated by the insertion probe flow meter however the correlator is still able to produce a good result of 0.6 meters from the location indicated by Sahara. When zooming into this correlation result in Figure 3, a small secondary peak can be seen 77.5 meters from sensor A. This could be the leak Sahara found at 82 meters. This leak had been exposed and partially plugged prior to our testing. The amount of noise generated by this leak will have been reduced significantly.

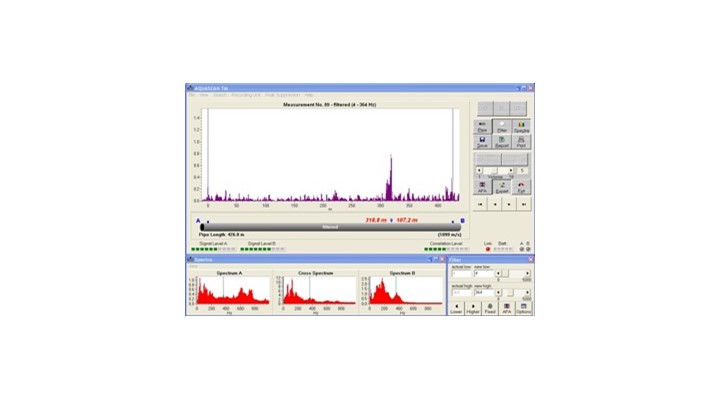

Figure 4 shows a correlation of another section of the Algesirus line that had been surveyed by Sahara. The pipe starts as a 750mm OD cast iron pipe from sensor A and then reduces to a 650MM OD Pipe at 56 Meters from sensor B. Sahara was unable to go through the valve on this reducer so the last 56 meters had not been surveyed. It took almost 7 hours to survey this section with Sahara. It took the Aquascan TM approximately 1 hour to survey the same section.

Sahara reported a small leak 94 meters from sensor A and two large leaks at 306 and 318 meters from sensor A. Aquascan TM’s correlation result clearly indicates a leak as 318.8 meters from sensor A. A secondary peak lies approximately 310 meters from sensor A. At 220 meters from sensor A there was a busy road. A small peak generated by this traffic can be seen on the graph however this seems insignificant in comparison to the peaks created by the leaks.

Figure 5 shows the longest distance correlated at 599.5 meters, with the most number of leaks. There are two large peaks very close together and close to sensor B. The largest peak is the closest to sensor B, this is a throttled valve. Our second peak has a 3 meter deviation from the leak location indicated by Sahara. This larger deviation will be caused by the long time delay with this long distance and the indicated leak position being on the far edge of the correlation. In addition to these large peaks there are small peaks to correspond with the small leaks found by Sahara at 106m, 201m and 303m. These peaks are small and may not have been picked prior to the repair of the big peaks. Now knowing these points are leaks, it is also possible the small peaks at 490 meters from A and 500 meters from A are also leaks. It would be interesting to investigate this.

Conclusions

Testing proved the Aquascan TM is effective at finding leaks in busy Asian cities over distances of 600 meters or more. The setup time for each correlation is about half an hour with the processing time being 15 to 30 minutes. This makes the Aquascan TM a fast and effective solution for finding leaks on Trunk Mains. Trunk main correlation locations need to be pinpointed the same way as leak detection in the distribution network. There are advanced automatic filtering options to enable the operator to quickly identify potential leak locations and suppress some of the background noise.